Drain Stack Ventilation Requirements for Plumbing Systems?

Key Takeaways

-

Drain stack ventilation is extremely important to the overall air circulation. This avoids the creation of harmful pressure imbalances and allows for efficient drainage in modern plumbing systems.

-

Appropriate venting is an important safeguard for letting sewer gases escape harmlessly. It protects trap seals and prevents noxious fumes from infiltrating your home.

-

Proper ventilation minimizes chances of clogging and backups, contributing to the durability and energy efficiency of plumbing systems.

-

For safe and effective installations, always follow and exceed local plumbing code and national standards. Don’t forget about the International Plumbing Code (IPC).

-

To vent properly, always make sure to properly size your pipes. Additionally, keep the appropriate distance between vents and fixtures and extend the vent above the roofline.

-

Routine inspection and use of proper materials are important best practices. They prevent blockages and keep the system running at peak efficiency.

A good understanding of drain stack ventilation requirements is crucial for maximizing the efficiency of a building’s plumbing system. Ventilation in a drain stack is essential for keeping appropriate air pressure. This prevents wastewater from flowing back uphill and prevents harmful sewer gases from intruding into residential spaces.

In a coordinated system, vent pipes tied to the exhaust stack protect proper function by maintaining safety. When designing your plumbing system, prioritize these issues, starting with pipe sizing and placement. Always adhere to local building codes, which often adopt standards like the International Plumbing Code.

With careful planning and installation, the chances of blockages, unpleasant odors, and system failures are greatly minimized. By keeping these requirements in mind, professionals can create plumbing systems that suit operational requirements. This thoughtful approach not only provides long-term reliability but fosters a healthy, compliant environment for building occupants.

What Is Drain Stack Ventilation

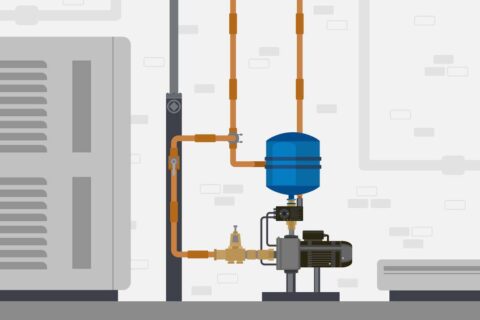

Drain stack ventilation is an essential component of plumbing systems. This is to allow air to flow through the drainage system, keeping pressure and vacuum in check, which in turn prevents drainage system failure. Without proper ventilation, air pressure can hinder the flow of water, resulting in poor drainage.

When air can move continuously, properly vented systems help everything run smoothly. When you flush a toilet or run a faucet, air pressure creates a rush of air through the vent stack. This creates equal pressure and prevents issues such as slow draining or gurgling noises.

Components of Drain Stack Ventilation

A common system consists of the following main components. The vent stack, a vertical, exterior pipe, gives these gases a path to escape outdoors safely. It ties in at the bottom of the drain stack.

Ensure you install it downstream, generally within 10 x stack diameter. For systems with a minimum of five branch intervals, plumbing codes require a vent stack. Larger systems, such as those installed in tall buildings, need relief vents.

To manage the pressure differentials properly, place these vents every ten branches. Common vents help by connecting two drainage systems to the main vent, allowing a steady flow of air.

Relationship to Waste Disposal Efficiency

As you can see, ventilation plays a crucial role in waste disposal. It stops clogs from forming by keeping a consistent air pressure. This prevents trap seals from drying out, protecting you from annoying smells and sewer gas escaping.

Well-vented systems allow fixture outlets, including sinks, toilets, and more, to operate freely, preventing the risk of backups or clogs. With the average American using 82 gallons of water each day, efficient drainage is extremely important.

Low ventilation levels can cause expensive premature repairs, the cost of replacement averaging $1,500 to $4,000.

Drain stack ventilation has many benefits. For one, it allows a safe outlet for sewer gases, decreasing the chance of toxic exposure. It protects trap seals, which are barriers to sewer gas that prevent odors from entering living spaces.

For example, a kitchen sink’s P-trap depends on good drain stack ventilation to maintain a water seal that keeps sewer gas from entering the home. Ventilation further benefits our plumbing fixtures, allowing water to pass through pipes unobstructed, freeing energy and pressure.

It prevents obstructions. The venting of the drain stack prevents the air from becoming trapped which would otherwise increase the risk of clogs and backups throughout the system.

We know that adequate plumbing system ventilation is essential to our system’s durability. It prevents the most common broken collar and clogging failure modes that can lead to lost efficiency.

In tall structures, where pressure differentials can be drastic, adequate venting provides pressure stability throughout the entire building. Proper ventilation is critical to health and safety, especially to prevent accumulation of harmful gases such as methane.

In addition to understanding how to use drain stack ventilation, compliance with local plumbing codes is key. Code requires vent stacks in systems with five or more branch intervals.

Following these standards will not only keep you and your workers safe, it can prevent the high cost of fines or repairs.

Key Requirements for Drain Stack Ventilation

Building Codes and Standards

Therefore, drain stack ventilation systems need to be installed according to accepted building codes for proper safety and functionality. The International Plumbing Code (IPC) offers detailed instructions down to the diameter of pipe used, number of vents, where they’re placed, and where they should end.

Following these requirements helps avoid sewer gas backflow and drainage collapse to protect public health and safety. Frequently, building officials will do inspections to ensure they are being installed correctly and with the appropriate materials.

A frequent pitfall is the failure to notice local amendments to the IPC, which may result in expensive rectifications. Other areas mandate secondary venting for tall buildings. This drives home the point that it’s important to know federal, state, and local laws inside and out.

Minimum Vent Pipe Size

The vent pipe size has a direct impact on airflow and drainage efficiency. The IPC requires that pipes of this vent stack have a minimum vent pipe diameter of 1 1/4 inch.

You’ll need bigger ones based on your fixture unit load. Pressure imbalances from undersized pipes can create situations with slow drainage or siphoning of trap seals.

For instance, a bathroom group with a sink, toilet, and tub/shower may need at least a 2-inch vent pipe to accommodate the load properly. When well-balanced, clogged drains and unpleasant odors are less likely.

Distance Between Vents and Fixtures

The distance between vent stacks and each fixture is highly significant to maintaining proper ventilation. Plumbing codes typically recommend that 1 1/4-inch pipes not run more than 6 feet horizontally.

For pipes 3 inches in diameter or greater, the maximum allowable distance jumps up to 10 feet. Too little or too much spacing can lead to improper ventilation and higher chances of clogging.

Things such as the layout of the building and accommodation of fixture also come into play affecting these distances. For example, in buildings with multiple stories, vents need to stack vertically to reduce the need for horizontal runs, allowing airflow to flow efficiently.

Proper Vent Termination

Vent pipes should always extend above the roofline to ensure gases are expelled safely. The IPC requires the vent to extend at least 6 inches above the roof, avoiding any backflow or odor problems.

Oftentimes, simple oversights, like ending vents too near a window or air intake, can allow harmful pollutants to infiltrate the air quality. Providing clear access to vent terminations is key for maintenance, and protecting long-term system reliability.

Regulations for Drain Stack Ventilation

Local Plumbing Codes

Local plumbing codes are the basis for drain stack air venting regulations. These codes outline the design, installation, and material requirements for venting systems in that jurisdiction.

For example, one could require a city to enforce minimum diameters for pipes, or particular vent stack arrangements from tall structures. Differences from jurisdiction to jurisdiction are such that what passes standards in one place may not pass muster in another.

It’s important for plumbers and contractors to understand the regulations of each jurisdiction they operate in. Only by understanding these regulations can they do their jobs safely and effectively.

Resources like your municipality’s website, your local building department or municipal trade association usually will have links to these codes. Careful review of local requirements can save consultants and contractors from expensive errors such as redesigns or local fines, while providing safe, efficient, and code-compliant installations.

National and International Standards

National and international standards provide invaluable resources for drain stack ventilation. These organizations are the American Society of Plumbing Engineers (ASPE) and the International Plumbing Code (IPC).

These standards establish minimum practices to make sure plumbing systems work as intended so that no one is exposed to dangers such as gas accumulation or lack of drainage. Organizations such as ASPE and the International Code Council (ICC) are always revising their standards.

They’re forced to do this by materials and technology so that they can stay ahead. Adhering to these widely accepted standards increases safety for all road users. It fosters meaningful plumbing professional credibility, demonstrating adherence to industry best practices.

Inspection and Compliance Guidelines

Inspections are an important tool to ensure drain stack ventilation systems are in compliance with today’s codes and standards. Inspectors often look to ensure that the vent pipe has been adequately sized, that vent pipes are installed correctly and that layout requirements have been met.

Written documentation, including cut sheets, as-built plans, and installation photographs, are critical in providing proof of compliance during these inspections. Contractors should get ready by familiarizing themselves with the licensing inspection checklist and making sure that all elements are accessible and clearly compliant.

This advance planning can reduce delays and prevent fines, leading to quicker project completion and approval, saving taxpayer dollars in the process.

Common Practices for Installation

1. Choose Appropriate Vent Materials

Choosing the best materials for vent stacks not only helps with performance, but can help you stay in compliance. PVC and ABS pipes are popular options for their low cost, corrosion resistance and ease of installation.

In high-temperature or more industrial environments, metal pipes such as cast iron or stainless steel provide increased strength. To be code-compliant, materials should always be rated for drain, waste, and vent (DWV) applications.

Using durable materials helps the system address environmental factors such as temperature shifting and humidity, allowing the system to last longer. Compatibility is important as well—pairing PVC pipe with metal pipe, for instance, requires specific transition fittings designed to avoid leaks.

A rubber coupling with stainless steel clamps can accommodate the joined material’s expansion and contraction while securely connecting dissimilar materials.

2. Ensure Proper Slope for Pipes

Maintaining a proper slope in vent pipes helps ensure drainage, which prevents puddling water. The best practice is to have a slope of 1/4 inch per foot at a minimum on all horizontal run.

Drifting from this plane can cause water to pool or create blockages. Common installation errors are bumpy surfaces or poorly aligned joints.

Use a level to check slope during installation and ensure that pipe hangers or supports are adjusted to maintain the required gradient.

3. Maintain Correct Pipe Connections

Tightening pipe connections avoids leaks and gaps that let air enter the system. Make sure joints fit.

Use solvent cement for PVC joints or threaded fittings on metal pipes, making sure that joints are a tight fit. Once everything is assembled, test all connections by running water through the system.

If you see dripping or hear dripping noise then corrective action is required.

4. Avoid Blockages in Vent Pipes

Preventive maintenance will help you avoid the potential for blockages. Debris, incorrect vent caps, or even birds’ nests can block airflow.

Check vents at least once a year and remove any blockages you can see. Signs of blockage include no drainage, slow drainage, or gurgling noises, which are key early indicators of a clog.

5. Test the System After Installation

A smoke test or air pressure test may be used to find leaks or blockages in the venting system. Ensure that all stack vents provide air movement and that rainwater drains freely.

Considerations for Effective Ventilation

With proper drain stack ventilation methods, we can prevent a malfunctioning or unsafe plumbing system, ensuring satisfactory service and compliance with venting provisions.

-

Assess the impact of building design on ventilation needs.

-

Know how air pressure affects venting.

-

Install new plumbing fixtures and traps to ensure sewer gas cannot escape into homes.

Impact of Building Design

The function and design of a building largely dictate its ventilation needs. Taller buildings will need more complicated venting systems. These systems are capable of handling the resulting higher pressure changes from bottom to top of the drain stack.

A large multi-story apartment complex will frequently need more vent stacks, or need a larger pipe diameter vent stack, than that of a single-story residential home. Considerations, such as having an open floor plan, can change airflow patterns and may require changing where vents are placed for efficient distribution.

Add air admittance valves or secondary vent stacks to improve air circulation. This strategy is particularly useful in buildings with deep or complicated floor plates. By planning properly, the venting system can address the specific requirements of the structure while still providing aesthetic appeal and continuity.

Role of Air Pressure in Venting

This shows how air pressure is critical to the effectiveness of drain stack ventilation. Proper air pressure keeps wastewater flowing smoothly and stops backflow from occurring or sewer gas from seeping in.

Improper vent placement or obstructions can lead to pressure imbalances. This can lead to traps siphoning and letting dangerous gases seep through. A system that utilizes branch pipes and balances air intake volumes to 90 to 110 percent of exhaust volumes keeps pressure even.

Systems that have an exhaust fan and make-up air hoods can best control pressure. This configuration further reduces problems such as crossdrafts greater than 100 ft/min. Conducting routine inspections and ensuring proper airflow at all times will largely mitigate any pressure-related issues.

Preventing Sewer Gas Leakage

Preventing sewer gas from leaking into your home is of utmost importance to the health and safety of your family. Sewer gases are a toxic combination of hydrogen sulfide (H2S) and methane. If they spread into your homes, they can cause potentially fatal health hazards.

Typical leaks come from broken seals, incorrectly placed vents or backed up pipes. Making sure all joints and connections have tight seals is essential. For instance, employing long-lasting materials and tight connections reduces the risk of leaks.

Properly venting systems helps prevent dangerous pressure buildup that can trap gases through vulnerable seams. To design systems that allow operators to safely control the flow of air and gases, use guidelines for adequate air exhaust. These standards outline the required cubic feet per minute for canopies and enclosing hoods.

Benefits of Proper Drain Stack Ventilation

Improved Drainage Efficiency

Ensuring the proper drain stack ventilation is essential for smooth flow of wastewater through pipes. Effective ventilation stops airlocks, which can halt or delay drainage. When air pressure is balanced, water drains quickly and completely—minimizing the chance of clogs and costly backups.

To give an example, in a kitchen sink, proper venting means your wastewater can drain fast without gurgling or backing up. Proper drain stack ventilation improves the performance of plumbing fixtures such as toilets and bathtubs. Without it, fixtures could drain poorly or even be susceptible to frequent clogs.

Periodic vent pipe maintenance like removing debris or checking for cracked pipes keeps vent stacks in perfect working order. A proactive homeowner who inspects their vent system before winter will save themselves from frozen drain disasters. This proactive measure is taken to guarantee proper drainage flow is maintained.

Prevention of Odors and Gas Build-Up

Proper venting provisions for drain stack ventilation are crucial for preventing awful sewer smells from infiltrating your home. This method helps maintain trap seals, the U-shaped pipes under sinks that stop sewer gases from leaking indoors. Effective ventilation is essential to prevent the accumulation of dangerous gases in plumbing systems, ensuring a safe environment.

Continuous airflow is the most important factor. Routine inspection will catch any blockages, such as leaves or a bird nest, which can disrupt the vent connection. This is particularly vital after fall, to ensure that air flow remains uninterrupted.

For residences where vent freezing is an issue in colder climates, insulated stack vents can avoid inconvenient disruptions. Addressing these issues promptly, like with our 15% OFF drain vent stack troubleshooting service, guarantees homes stay free of foul odors.

Enhanced Durability of Plumbing System

An effective system improves the lifespan of plumbing elements by lessening the impact of pressure and air flow on pipes and other components. Inadequate venting can create destructive pressure differentials, resulting in premature rupture or fracture of pipes.

Avoiding these problems will improve not just longevity of your plumbing but decrease the chance of expensive repairs. As an example, a home that has the proper venting installed in it will save the cost of replacing pipes due to repeated airlocks or poor drainage.

You can increase your system’s lifespan by regularly maintaining your system. Reduce costly property damage and ensure your drainage system operates as intended by clearing blockages and checking vent pipes after severe weather.

Conclusion

Drain stack ventilation is critical to the overall health of plumbing systems. It prevents sewer gases, ensures uninterrupted water flow and protects against pressure issues. Adhering to the proper requirements and regulations will help ensure that your system is functioning properly and is safe over time. Proper installation and planning keeps your home, and the environment, safe.

Prioritizing strong ventilation goes a long way. It cuts down on repair time and costs, saving you money, and enhances your space’s air quality. Easy measures such as ensuring proper ventilation and using materials that stand the test of time make a lasting difference.

Whether you’re deep in the midst of a design project or simply looking to test the waters of your own setup, start with these fundamentals. To get more advice or step-by-step instructions, visit other reliable resources. Some simple maintenance and smart steps can help ensure a dependable, healthy home plumbing system.

Frequently Asked Questions

What is drain stack ventilation?

Drain stack ventilation, an essential component of a conventional venting system, keeps air flowing through your plumbing system, preventing harmful sewer gases from entering your home and facilitating wastewater flow.

Why is drain stack ventilation important?

Without the right amount of venting provisions, plumbing systems become prone to clogs, slow drainage, and noxious smells that make their way into your home. This helps them stay compliant with building code requirements and contributes to a safe, odor-free environment.

What are the key requirements for drain stack ventilation?

Important requirements such as sizing the appropriate vent pipe diameter, proper vertical placement of stack vents, and adhering to local building codes can be critical to success in a conventional venting system. As always, please contact a licensed plumber for specific advice.

Are there regulations for drain stack ventilation?

Indeed, federal regulations are set forth in plumbing codes, including the International Plumbing Code (IPC) and Uniform Plumbing Code (UPC), which outline design, installation, and sizing requirements for venting provisions.

What are common practices for installing drain stack ventilation?

It’s common practice to install stack vents a minimum of 6 inches above the roof surface, ensuring they remain clear of blockages like tree branches or snow drift, to maintain effective venting provisions.

How can I ensure effective drain stack ventilation?

Ensure all stack vents are the right size, located correctly, and free from any blockage. Regular inspections by a certified master inspector can help maintain satisfactory service and keep your vent system operating at peak efficiency.

What are the benefits of proper drain stack ventilation?

With added ventilation methods, sewer odors are eliminated, drainage proves more efficient, and sewer-related plumbing issues, such as those involving stack vents, are minimized, providing a more robust home environment in terms of health and safety.