Air Duct Sealing Services in Centennial, CO Diagnostic & Repair Experts

Key Takeaways

-

Duct sealing saves energy and cuts heating and cooling costs by preventing loss and helping HVAC systems operate more efficiently and last longer. Just schedule a professional inspection to measure savings and monitor bills pre and post work.

-

Sealed ducts enhance indoor air quality by preventing dust, allergens, mold spores, and outdoor pollutants. Pair sealing with cleaning and list typical air-quality issues to watch post-service.

-

Thorough sealing work will be accompanied by diagnostic inspection, focused sealing with mastic, foil tape or Aeroseal, and verification tests after the work is complete. Demand a written report and results from verification testing from your contractor.

-

Centennial’s climate and altitude mean properly sealed, insulated ducts are a must for consistent indoor temperatures and humidity control. Capture and measure room temperature and humidity before and after sealing to quantify improvements.

-

Select pros for full-system scope, specialized tools, and expertise that tackle hidden leaks and altitude-specific challenges. Verify certifications, warranties, and what components are actually covered before you hire.

-

Don’t think of sealing as an isolated activity, but as one component of a broader HVAC strategy that includes system balancing, insulation inspections, and seasonal tune-ups. Schedule a follow-up with the provider to keep efficiency and indoor comfort.

Duct sealing Centennial refers to the sealing of leaks in HVAC ductwork in Centennial, CO. It prevents energy loss, enhances indoor air quality, and trims heating and cooling expenses by quantifiable margins.

Licensed professionals identify leaks using pressure testing and seal joints and seams with mastic or foil tape. Homeowners typically experience quicker temperature equilibrium and reduced bills post-service.

The body discusses techniques, prices, and selecting a contractor.

Sealing Significance

When your ductwork is sealed correctly, it prevents a significant energy waster and lays the foundation for improved indoor air quality, more consistent HVAC operation, and indoor comfort. The subtopics below parse the top advantages and real-life takeaways for homeowners and building managers in Centennial and comparable climates.

1. Energy Savings

Sealing significance – Duct sealing can reduce heating and cooling bills by preventing leaks that dissipate conditioned air. Leaky ducts are responsible for as much as 30% of a building’s energy loss, and sealing can shut 90% of those leaks, so bills drop and usage stabilizes.

Minimized loss preserves set temperatures without compelling your furnace or AC to run longer, saving homeowners energy and monthly costs and businesses operating costs. In the long run, less runtime translates into fewer urgent repairs.

A straightforward comparison table of energy bills pre- and post-sealing, indicating typical percent savings and kWh or m3 reductions as well as cost changes in a common currency, clarifies the impact for decision makers.

2. Air Quality

Sealed ducts close pathways that allow dust, pollen, mold spores, and outdoor pollutants to seep into living spaces. This minimizes allergen dispersion and is advantageous for those with asthma or sensitivities.

The significance of sealing is that sealing professionally, along with duct cleaning, can remove the dust and substances that cause odor and off-gassing, making it smell like “clean air.” Typical issues include dusty vents, musty odor, apparent mold, and constant allergies.

These issues can be fixed by cleaning or by sealing. In damp regions, moisture-resistant sealants assist in minimizing mold right at the origin.

3. System Longevity

By minimizing leakage, it decreases pressure on blowers, compressors, heat exchangers and other HVAC components. With less air leakage, your system hits set points faster and cycles less, leading to less wear and a longer equipment life.

Routine service with sealing and inspection prevents expensive failures and early replacement. Monitor system lifespans with records of runtime hours, repair rates, and replacement dates to measure gains over the span of years.

4. Home Comfort

Sealed ducts provide more uniform airflow so rooms achieve set temperatures without large fluctuations. That minimizes hot and cold spots and eliminates drafts from busted seams.

Enhanced airflow minimizes noise from turbulent leaks and rattling ducts too. Common comfort problems solved by sealing are unbalanced heating, distant rooms with little airflow, and noisy vents. A lot of these things clear right up once they’re adequately sealed.

5. Environmental Impact

Less wasted energy equals less carbon spewed. Well-strategized HVAC systems use less electricity and fuel, complementing other efficiency efforts.

Sealing properly lasts for years. You can build a building up to modern standards and keep the long-term environmental cost lower.

Centennial’s Climate

Centennial’s climate, with its chilly winters, hot summers, and dry atmosphere, necessitates efficient ductwork to maintain both year-round comfort and indoor air quality. The semi-arid conditions typical of the Denver metro area translate to low humidity much of the time, dust and even wildfire smoke, all of which enhance the demand for dependable duct insulation and tight sealing.

Local conditions interact with building systems: the low average humidity, around 30 to 40 percent in winter, wide temperature swings, and elevation together raise the stakes for correct sealing and periodic cleaning, including options such as Aeroseal Colorado for hard-to-reach leaks.

Temperature Swings

Experience Centennial’s climate. Leaky ducts push conditioned air into uninsulated spaces, making for the hot or cold spots homes in the neighborhood frequently experience during seasonal transitions.

Well-repaired and well-sealed ductwork does not just prevent heat from escaping during winter; it limits cool air loss during the summer, which reduces the strain on your HVAC system and minimizes energy waste. Monitor room temperature variation before and after sealing to see measurable results.

Simple spot checks with an infrared thermometer or smart sensors can reveal differences of several degrees in problem rooms.

Dry Air

Centennial’s dry climate can exacerbate air leaks and decrease comfort if ducts aren’t sealed. Duct sealing keeps conditioned, moistened air inside living spaces instead of being exhausted into the crawlspace or attic, which assists the whole home humidifier in maintaining set humidity levels.

Dry air increases dust; homes in Centennial typically experience more dust accumulation than those in humid areas, making sealing combined with regular duct cleaning essential to keeping allergens in check. Duct sealing is great for humidity, too: more stable indoor moisture, less humidifier and dehumidifier cycling, and less dust recirculation, all of which feel more comfortable.

Altitude Effects

Higher altitude impacts HVAC performance and makes duct sealing more critical. Thinner air at elevation modifies heat transfer and can cause leaky ducts to lose more energy relative to sea-level homes.

It takes seasoned HVAC installers who understand how to test static pressure, airflow, and sizing of the system in these local conditions to fix altitude-specific problems. The same system at a higher altitude measures energy and airflows with ducts sealed and unsealed.

Real-world tests reveal reduced runtime and more controlled temperature after professional sealing.

The Sealing Process

A transparent, phased plan allows homeowners to know what to anticipate when air duct sealing in Centennial. It starts with inspection, flows into focused sealing work, and concludes with inspection and documentation to display results and future action.

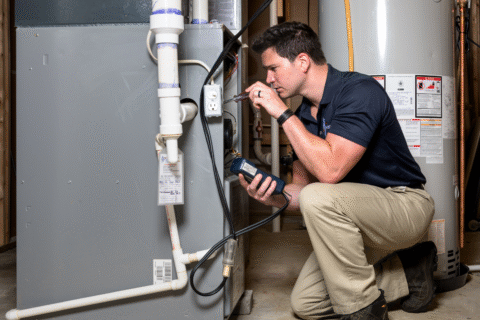

Inspection

The inspection identifies concealed air leaks, disconnected ducts and loose connections hiding behind walls or in attics. Technicians visually examine vents and ductwork for tears, holes or crushed sections and inspect accessible attic and basement runs during a full check.

They employ duct cameras to look inside long runs and spot damage that visual inspections miss. Airflow testing and pressure measurements provide accurate diagnostics. A blower door or duct blaster test measures how much leakage exists and identifies where repairs should be concentrated.

Inspectors document their results in an extensive checklist that details location, type of damage, approximate leak surface area, and suggested repair approach. Periodic inspections, every three years or so, help avoid expensive damage and keep it working well.

Sealing

Sealing seals joints, seams and openings to form an airtight system. Experts use mastic sealant, UL 181-rated foil tape, or aerosols such as Aeroseal, depending on duct material and access.

Mastic or foil tape are typical for visible cracks and accessible seams, while aerosol methods can seal hidden leaks deep inside the network. Technicians focus on obvious gaps and subtle leak points around boot connections, seams and connections to HVAC units.

Sealing properly restores airflow balance and can reduce duct-related energy loss, which research finds may amount to as much as a third of heating and cooling waste. Homeowners should know material choices: mastic for long-lasting joints on sheet metal, UL 181 tape for flexible ducts, and aerosol seals where access is limited.

Typical costs vary. Traditional sealing often runs US$300 to US$500, while aerosol-based work may exceed US$1,500.

Verification

Verification testifies to the fact that the system is better and leaking less. Once sealed, teams redo pressure and airflow tests and employ diagnostic tools to analyze before-and-after results.

Significant reductions in leakage and enhanced airflow measurements demonstrate that the work satisfied both technical and customer expectations. Technicians deliver a summary report with test data, duct-camera photos and a list of repairs made so you can be confident about the process.

Annual cleaning is recommended to remove dust and debris and to help maintain sealed ducts, and owners should keep inspection records for future service.

Materials Matter

Materials Matter: It’s a simple truth that the quality of the materials directly impacts the longevity of how well a duct seal holds. For within reach seams, a bit of UL-rated mastic duct sealant and UL 181 metal foil tape is the time-tested go-to. They have to withstand the temperature fluctuations and air flow inside ductwork and must be approved for use inside supply ducts.

The ones that aren’t tend to either not stick or off-gas. If applied correctly, duct seals can last 15 to 20 years or more, but only when surfaces are clean, dry, and primed prior to application.

Mastic Sealant

Mastic is a paste-like thick sealant that seeps into joints and seams and sets to a flexible, airtight layer. It adheres nicely to metal, fiberglass, and select flexible ducts and withstands the temperature extremes of attics and basements.

Mastic is a durable barrier to air leaks and water intrusion when UL-rated products are utilized. Benefits over the alternatives include better gap-filling ability, flexibility after cure, and vibration resistance to cracking.

Manual application steps: Clean the area, remove dust and loose material, apply mastic to the gap, smooth for full contact, and allow cure per manufacturer instructions. This technique is optimal for oversize, accessible seams and when you need a tough, paint-like finish.

Foil Tape

Foil tape is a thin, adhesive-backed tape designed to patch up tiny leaks and cracks on metal ducts in a flash. It is incredibly durable and withstands harsh temperature and humidity conditions without cracking or losing adhesion.

Mostly used in conjunction with mastic, foil tape strengthens seams and offers instant protection during mastic curing. It is ideal for patch repairs on hard metal ducts, around flanges, and quick fixes where little prep is possible.

Don’t skimp—use UL 181-rated metal foil tape for long-term performance because nonrated tape will peel or fail under duct conditions. For big, simple sealing jobs, foil-backed mastic tape provides a speedier alternative that still requires a finishing mastic topcoat.

Aeroseal

Aeroseal is a technology that sends aerosolized sealant droplets into the ductwork to seal leaks from within. Particles travel through air and settle at leak locations, depositing seals without having to reach every hole directly.

It comes in particularly handy for leaks behind walls, floors, or ceilings, where manually sealing is impossible. Aeroseal Colorado provides this service for Centennial homes that want the most effective system possible and the measured results to prove it.

Typical Aeroseal process: run a baseline duct leakage test (CFM25 at 25 Pa), isolate the system, inject aerosol sealant while the system runs at a controlled pressure, monitor leak reduction in real time, and perform a post-seal leakage test. The result is a quantifiable decrease in CFM and frequently enhanced comfort and less energy consumption.

|

Material |

Best Use |

Longevity |

Notes |

|---|---|---|---|

|

UL-rated mastic |

Joints, seams, large gaps |

15–20+ years |

Requires surface prep and cure time |

|

UL 181 foil tape |

Small gaps, metal ducts |

10–15 years |

Use with mastic for best results |

|

Aeroseal aerosol |

Inaccessible leaks |

Varies, often long-lasting |

Seals from inside; needs testing equipment |

Professional vs. DIY

Professional duct sealing provides a full process: inspection, cleaning, sealing, and verification. They actually map out the system, test for leaks, use the right sealants, and retest. DIY sealing saves money but typically ends at sight lines and cracks, leaving concealed leaks and issues exposed.

Scope

Professionals take care of the entire duct system, including supply and return ducts, branch lines, plenums, and connections to equipment. They trace airflow paths, inspect dampers, and check insulation and ducts in crawlspaces, attics, and basements.

This whole-system perspective is needed because leaks in returns or buried runs can sabotage efforts to fix visible runs. DIY efforts usually focus on accessible parts: register boots, exposed seams, or attic trunks. Those fixes assist but regularly overlook deep leaks, collapsed sections, or undersized ducts that restrict airflow.

Tricky problems like failed ducts, significant corrosion, or undersized runs need to be re-engineered or replaced, not just patched. Professionals can isolate system-level issues and suggest repairs or upgrades. They can suggest targeted cleaning, sealing, or partial replacement when necessary.

Checklist: supply and return registers, main trunks, branch lines, plenums and collars, HVAC unit connections, access panels, insulation integrity, dampers and balancing hardware, visible corrosion or crush points.

Tools

Pro HVAC techs use diagnostic tools like duct blasters, pressure testers, thermal imaging, particle counters, and duct cameras. For sealing, they use mastic, UL-classification tapes, aerosol-based sealants for the entire system, and industrial applicators.

These tools allow them to discover concealed leaks, quantify leakage in cubic meters per hour, and verify performance after sealing. I mean, what DIY-er has access to a duct camera or proper pressure testing or industrial-grade materials?

Home seal kits and foil tapes are great for small gaps but fall flat when you’re dealing with larger leaks or porous joints, which means rework. If you do it yourself with the wrong materials, you risk glue failure, leaky spots, and time lost.

Essential tools for proper work include a pressure tester or blower door connection, an inspection camera, mastic and brushes, UL-approved aluminum tape, an aerosol duct sealant kit for whole-house sealing, gloves and masks, and basic hand tools.

Expertise

Professional technicians know how to locate root causes and implement the appropriate solution. They’re schooled on air flow, codes, and safety limits for contaminant and insulation handling. They adhere to local building codes and OSHA exposure limits in cramped or dusty spaces.

Licensed contractors may provide warranties or performance guarantees on both materials and labor, minimizing the likelihood of return visits. Seek out HVAC certification, NADCA membership, and experience with whole-house duct sealing.

DIY can indeed be a learning adventure; it’s labor intensive and you might need several tries.

Beyond The Seal

Duct sealing fixes leaks and indoor air, yet it’s one piece of a broader push to maintain an HVAC system efficient, safe, and comfy. A complete design considers airflow balance, insulation on exposed ducts, and maintenance as well. Below are the critical follow-up complementary steps to sealing, with actionable details and examples homeowners can implement.

System Balancing

System balancing ensures air flows uniformly so every room attains the set temperature. Technicians verify room-by-room conditions, measure airflow with an anemometer or flow hood, and adjust dampers and vent registers to balance under- or over-supplied zones. They could adjust thermostat settings or suggest zoning controls for bigger homes.

Balancing minimizes noisy drafts and rattles from turbulent flow, and it prevents short-cycling that wastes energy. A typical balancing procedure includes measuring baseline flows, closing or opening dampers incrementally, re-measuring flows, and recording final settings for future reference.

For example, a bedroom that was 3 to 4 degrees Celsius cooler than the rest of the house might need its supply reduced elsewhere and a slight damper opening to that room to equalize temperature.

Insulation Check

Ducts in attics, crawlspaces or unheated basements dissipate heat or cold if insulation is inadequate. Experts check insulation R-values for crushed or missing batts and identify ‘batt’ areas where sealing and insulation both count, like flex duct runs with holes.

On top of sealing, proper insulation helped preserve the conditioned air temperature and prevented moisture from seeping into ducts, causing mold. If you notice huge temperature swings, condensation on ducts or visible damp spots, it’s a pretty good indicator that you have inadequate insulation.

Suggested remedies vary from installing insulation wraps, such as installing 50 to 100 millimeters of mineral wool, to swapping out damaged pieces or using closed-cell foam in inaccessible regions.

Regular Maintenance

Maintenance — professional cleaning, filter changes, and periodic inspections — keeps the sealed system working as intended and protects indoor air quality. Regular maintenance stops the accumulation of dust, pet dander, and microbial growth that can slip past even a sealed system via returns or fresh-air intakes.

Maintenance extends equipment life by keeping fans and coils clean, which lowers energy consumption and repair expenses. Homeowners should adopt a checklist: replace filters every 1 to 3 months, inspect visible ducts annually, schedule a professional cleaning or inspection every 3 to 5 years, and log any unusual smells or noise for technician review.

A few individuals mention fewer allergy flare-ups and greater all-around comfort after instituting this routine.

Conclusion

Air duct sealing centennial reduces waste and makes houses feel more solid. In Centennial’s dry, high-elevation climate, a nice seal keeps air flow consistent and spares wear and tear on HVAC components. Use tried and true materials like mastic or metal tape and tailor the repair to leak size. Hire a pro for large runs, complicated layouts, or if you want a duct test. Give a quick DIY patch a whirl with tiny, easy-access gaps. For the greatest benefits, combine sealing with filter maintenance and insulation. For a concrete next step, receive a quote from a local contractor or conduct a simple leak check on your own to determine your point of departure.

Frequently Asked Questions

What is air duct sealing and why does it matter in Centennial?

Air duct sealing seals leaks in HVAC ductwork. It minimizes energy waste, increases home comfort and decreases your energy costs. These advantages count in Centennial’s seasonal temperature variations.

How do I know if my ducts need sealing?

Check for inconsistent heating or cooling, elevated energy bills, dusty AC registers, or exposed duct seams. A professional leak test, known as a duct blaster, verifies.

What sealing methods are best for residential ducts?

Mastic sealant, UL-listed foil tape, and aerosol-based sealants are popular. Mastic is used for seams, foil tape is used for joints, and aerosol is used for unreachable leaks.

Should I hire a professional or try DIY sealing?

Air duct sealing centennial DIY is fine for little, obvious leaks with mastic or foil tape.

How much can sealing save on my energy bills in Centennial?

Savings differ, but average homes save between 10 and 30 percent on heating and cooling costs when significant leaks are repaired. Savings vary based on home size and current duct condition.

Will sealing improve my indoor air quality?

Yes. Sealing cuts infiltration of dust, pollen, and outside pollutants. Combine with routine filter replacements and ventilation for the best effect.

How long does duct sealing last and what maintenance is needed?

That’s how good sealing can last for years. Have ducts inspected every two to three years and after major HVAC work. Reseal any new or reopened joints.