Commercial Kitchen Ventilation Requirements: A Comprehensive Overview

Key Takeaways

-

Having an understanding of kitchen ventilation requirements is an essential part of creating a safe and efficient cooking environment in commercial kitchens.

-

Exhaust systems are critical to commercial kitchens. They remove heat, smoke, and odors, which means a safe, high-quality air experience.

-

Kitchen hoods help trap and vent unwanted airborne particles. Appropriate design and installation are essential to their effectiveness.

-

Regular maintenance practices for ventilation systems, such as cleaning and inspections, help prevent hazards and ensure optimal performance.

-

Proper ventilation creates better work conditions in commercial kitchens by improving the air quality and decreasing the possible health risks.

-

Proper ventilation systems help meet health and safety regulations, ensuring the safety of employees and clients.

You may be asking yourself… Why does kitchen venting really matter? It’s not just about blowing away the smoke. A good system keeps your kitchen safe and in compliance with rules.

We’re discussing the nitty-gritty of hoods—each type, its job, and why they’re non-negotiable. From grease-catching baffle filters to sleek canopy hoods, each plays a role in safety.

Safety compliance is huge, obviously. It’s not just a matter of installing and forgetting. Regular checks and upkeep keep things running smoothly.

Ventilation isn’t a set-and-forget deal. Professional oversight is important. Inspections catch issues before they get big.

Safety and efficiency go hand in hand. We dive deep with these essentials. You receive a kitchen that is safe and compliant.

Let’s break it down and make sense of it all.

What Are Kitchen Ventilation Requirements

To ensure a safe cooking environment, a reliable commercial kitchen ventilation system is essential for managing cooking vapors and maintaining good air quality. Proper kitchen ventilation design includes the installation of commercial kitchen exhaust hoods, which effectively remove grease vapors and other airborne pollutants generated during cooking operations. Additionally, adherence to commercial kitchen hood code requirements ensures compliance with safety regulations, providing a critical safety requirement for all kitchen operators.

1. Definition of Kitchen Hoods

Kitchen hoods, also referred to as range hoods or exhaust hoods, play a crucial role in maintaining good air quality within modern kitchens. These commercial kitchen ventilation systems effectively eliminate smoke, steam, and odors while cooking. By pulling out cooking vapors and grease, they help create a safe cooking environment, ensuring compliance with commercial kitchen hood code requirements.

In commercial kitchen settings, where cooking operations can be intense, hood exhaust systems are not just a luxury but a critical safety requirement. They efficiently manage airborne pollutants and maintain proper kitchen ventilation, which is essential for the health of kitchen operators and patrons alike. Proper grease management practices and reliable kitchen environment solutions contribute to a compliant cooking environment.

2. Functionality of Kitchen Hoods

Kitchen hoods serve as the lungs of the kitchen, effectively filtering out unwanted elements like smoke, grease, and odors, which is vital for maintaining a healthy home environment. This essential function directly influences kitchen safety and efficiency, particularly in a commercial kitchen setting. By ensuring proper kitchen ventilation through commercial kitchen exhaust systems, these hoods help mitigate fire hazards, a significant risk in any type of commercial kitchen.

Moreover, the functionality of kitchen hoods is crucial for creating a safe cooking environment. A well-designed kitchen ventilation system not only enhances air quality but also plays a pivotal role in meeting commercial kitchen hood code requirements. By effectively removing cooking vapors and airborne pollutants, kitchen hoods contribute to a reliable and compliant cooking environment, ultimately supporting the overall safety and efficiency of cooking operations.

3. Varieties of Kitchen Hoods

The same is true when it comes to kitchen ventilation systems — it’s not a one-size-fits-all scenario. There are two main types of commercial kitchen exhaust hoods: Type I and Type II. Type I hoods are best suited for appliances that generate smoke or grease, such as grills and fryers, while Type II hoods are designed for equipment that produces heat and steam, like dishwashers or coffee machines.

Choosing the right hood type is essential to maintaining a safe cooking environment and ensuring efficient kitchen operations. Understanding the technical specifications of each hood type helps in selecting the appropriate commercial kitchen ventilation design. Here’s a quick breakdown of the different hood systems and their applications.

In modern kitchens, proper kitchen ventilation is crucial for managing cooking vapors and providing a reliable kitchen environment. The right commercial kitchen ventilation system not only improves air quality but also adheres to fire safety regulations, ensuring compliance with commercial kitchen code requirements.

|

Hood Type |

Used For |

Example Appliances |

|---|---|---|

|

Type I |

Smoke/Grease |

Grills, Fryers |

|

Type II |

Heat/Steam |

Dishwashers, Coffee Machines |

4. Overview of NFPA 96 Safety Standards

NFPA 96 establishes the standard for kitchen ventilation safety, emphasizing the importance of a commercial kitchen ventilation system. It points toward critical standards, such as the necessity of regular inspections for commercial kitchen exhaust hoods. Additionally, it specifies that all grease-laden vapor paths must be liquid-tight, which is crucial for the proper grease management practices necessary to prevent the risk of a fire.

These standards are vital not only for safety but also for compliance with commercial kitchen hood code requirements. Ignoring them can lead to serious safety and legal problems, including the risk of airborne pollutants and contaminated air. Compliance with these regulations is essential for maintaining a safe cooking environment and ensuring that commercial kitchen operators meet the rigorous safety standards required in the industry.

Proper ventilation is crucial for the efficient operation of kitchen appliances and the overall functionality of a commercial kitchen. The NFPA guidelines help ensure that kitchen operators implement an effective kitchen ventilation system, which is vital for managing cooking effluents and maintaining good air quality. Adhering to these standards ultimately contributes to a reliable kitchen environment, safeguarding both staff and patrons alike.

5. Importance of Compliance and Oversight

It’s not just a suggestion — adhering to local regulations for a commercial kitchen ventilation system is a necessity. The regular oversight ensures effective exhaust hood systems are in place, which helps avoid mishaps and maintains a safe cooking environment.

Training kitchen staff on safety protocols is equally important because a well-informed team is a safe team, especially when it comes to understanding commercial kitchen exhaust systems and their technical specifications.

If we look at compliance and oversight, there is substantial risk involved with improper kitchen ventilation systems. This area is crucial for any commercial kitchen operation, as it directly impacts fire safety and overall kitchen efficiency.

Exhaust Systems in Commercial Kitchens

Core Components of Exhaust Systems

The first step to setting up a commercial kitchen is understanding the essential parts of an exhaust system. These systems typically include fans, ducts, and filters.

They work together to eliminate smoke, heat, and odors. Think of the fan as the heart, pumping all that bad air out.

The ducts are the veins, carrying the air out. Filters, on the other hand, catch grease and particles, keeping that airflow clean and safe.

Choosing high-quality materials for these components is key. You want parts that’ll last and can withstand the heat and grease of a busy kitchen.

Additionally, the components have to work together well. If the fan is too weak, the system can struggle to get going.

Moreover, narrow ducts can negatively affect performance, making it challenging for the dryer to effectively remove air.

Grease Filtration and Management Techniques

Controlling grease is a huge priority in kitchen exhaust systems. You just need good grease filters to catch it before it creates problems.

Regular cleaning is the name of the game here; dirty filters cause grease fires that are dangerous and expensive. As a best practice, clean filters on a set schedule depending on how much you do your cooking.

Nobody wants a fire to break out just like that.

Grease traps are important, too. They keep grease out of the pipes to prevent clogs.

Cleaning out these traps helps your kitchen remain safe and sanitary. If you follow these steps, you will avoid a lot of headaches in the future.

Access Doors for Duct Maintenance

Access doors are a necessity when it comes to a commercial kitchen ventilation system. They provide essential access to clean the ducts, which is crucial for the efficient operation of the exhaust system. Without these access doors, it becomes challenging to inspect and maintain the kitchen exhaust system, potentially leading to issues with grease buildup and airflow. Sealing these doors tightly is also vital, as air escapes can disrupt the overall efficiency of the hood exhaust systems.

Moreover, access doors assist with safety compliance in commercial kitchen applications. Regulations often mandate regular inspections of the exhaust hood system, and these doors simplify that process significantly. No one wants to compromise on safety standards, especially in a busy commercial kitchen setting. Ensuring that safety protocols are adhered to is imperative for maintaining a safe cooking environment.

Access doors also play a vital role in facilitating these inspections and ensuring compliance with commercial kitchen hood code requirements. By allowing easy access for maintenance and cleaning, they help kitchen operators uphold rigorous safety standards. This is particularly important in environments where cooking appliances generate cooking vapors and grease, as proper grease management practices are essential for fire safety.

In conclusion, access doors are an integral part of the exhaust hood system design, ensuring that the commercial kitchen ventilation system operates effectively and safely. Their presence not only enhances the efficiency of the duct system but also contributes to creating a reliable kitchen environment, where safety and compliance are prioritized.

Standards for Exhaust Systems

When discussing regulations, it’s essential for commercial kitchens to adhere to specific standards to ensure safety and efficiency. The NFPA 96 Standard serves as a crucial guide, addressing aspects such as proper kitchen ventilation and fire suppression systems. Staying compliant with these commercial kitchen hood code requirements necessitates regular inspections and thorough documentation, which can help identify patterns of common problems.

The NFPA 96 Standard outlines critical safety requirements, covering everything from the design of kitchen ventilation systems to the installation of commercial kitchen exhaust hoods. This comprehensive approach ensures that kitchens maintain a reliable kitchen environment while effectively managing cooking vapors and grease. Understanding the technical specifications for different hood types is vital for compliance.

Regular inspections not only help maintain compliance but also contribute to a safe cooking environment. By documenting adherence to the NFPA 96 Standard, kitchen operators can ensure that their commercial kitchen ventilation systems are functioning optimally, addressing any potential issues before they escalate. This proactive approach is essential for maintaining a compliant cooking environment.

In summary, following the NFPA 96 Standard is paramount for commercial kitchen operators. By focusing on proper kitchen ventilation and fire safety regulations, kitchens can achieve efficient cooking operations while minimizing risks. Regular inspections and adherence to commercial kitchen ventilation design systems are key components in maintaining a safe and efficient kitchen space.

|

Requirement |

Key Details |

|---|---|

|

Make-Up Air Rate |

10% of exhaust hood airflow, evenly distributed |

|

Inspection Frequency |

Based on cooking volume and types |

|

Grease Filter Access |

Must be easy to remove and clean |

|

Separation Distances |

Specify between grease devices and cooking surfaces |

Role and Design of Kitchen Hoods

In commercial kitchens, the kitchen hood serves as a crucial component of the kitchen ventilation system. This essential equipment effectively removes smoke, heat, and grease, ensuring a safe cooking environment while maintaining good air quality. In a bustling restaurant, the commercial kitchen exhaust hood works tirelessly to keep the air clean and breathable for kitchen operators.

The importance of proper kitchen ventilation cannot be overstated, especially in busy cooking operations. The exhaust system, including various hood types like type II hoods, is designed to handle cooking vapors and ensure compliance with commercial kitchen hood code requirements. This system prevents the buildup of airborne pollutants, creating a reliable kitchen environment for chefs and staff alike.

Additionally, efficient grease filters and exhaust ducts systems play a vital role in managing cooking effluents. By incorporating these elements into the commercial kitchen ventilation design, operators can achieve optimal performance and safety. With a well-designed exhaust hood system, restaurants can focus on delivering exceptional culinary experiences while ensuring a compliant cooking environment.

Significance of Hood Size and Configuration

The size and shape of the kitchen hood are crucial in ensuring a reliable kitchen environment. It’s not just about placing any old hood over the stove; a well-designed commercial kitchen ventilation system is essential. The right size allows the hood to effectively capture smoke and grease, which is vital for maintaining good air quality. If the size is incorrect or the fit isn’t right, you’ll encounter serious ventilation issues.

Poor airflow can lead to a range of problems, including the accumulation of cooking vapors and grease, which can compromise safety. This is where kitchen operators often trip up: they forget to calculate the necessary ventilation. Accurate measurements for the commercial kitchen exhaust hood dimensions are key to achieving optimal performance.

Getting it wrong can result in a smoky mess and inefficient grease management practices. Proper configuration of the exhaust hood systems ensures that air flows effectively, preventing the buildup of airborne pollutants. This is particularly important in a commercial kitchen setting, where cooking operations generate significant cooking loads and require robust ventilation solutions.

Moreover, understanding the different hood types, such as type II hoods, is essential for compliance with commercial kitchen hood code requirements. Each type serves specific cooking applications, and selecting the right one can significantly enhance the overall efficiency of the kitchen ventilation design.

In summary, ensuring that the commercial kitchen exhaust system is appropriately sized and configured is an important safety requirement. It not only helps maintain a safe cooking environment but also supports efficient kitchen operations, allowing kitchen services to run smoothly and effectively.

Type I Hood Standards and Guidelines

Type I hoods are essential for commercial kitchen applications that produce smoke or greasy fumes, such as deep fryers and grills. These commercial kitchen exhaust hoods require specific construction materials to ensure safety and compliance with commercial kitchen hood code requirements. Proper kitchen ventilation is crucial to managing cooking vapors effectively.

Labeling is vital for exhaust system requirements, as it guarantees that the hood operates efficiently while meeting fire safety regulations. This proper labeling helps maintain the necessary ventilation and ensures the safety of kitchen operators.

Securing these hoods correctly is imperative to prevent accidents in a busy kitchen environment. Ensuring that the commercial kitchen ventilation system is properly installed and maintained can significantly reduce potential hazards, creating a safe cooking environment for all.

Type II Hood Standards and Guidelines

You have your Type II hoods, which are essential components of a commercial kitchen ventilation system. These hoods are specifically designed for heat and steam, as seen over dishwashers. They offer flexibility, sometimes even eliminating the need for ductwork, making them a cost-effective option for kitchen operators.

Sealing the joints and seams of these hoods is crucial for proper kitchen ventilation. This practice ensures everything remains tight and efficient, effectively managing moisture and steam while providing a reliable kitchen environment.

In modern kitchens, the integration of commercial kitchen exhaust systems is vital for maintaining a safe cooking environment. These systems not only help in controlling cooking vapors but also play a significant role in fire safety, ensuring compliance with commercial kitchen hood code requirements.

Here’s a quick comparison of various hood types and their applications, highlighting the importance of appropriate ventilation in commercial cooking operations. Understanding the technical specifications of each hood system can enhance kitchen efficiency and safety, ultimately improving the cooking experience.

|

Hood Type |

Use Cases |

Cost Range |

Special Features |

|---|---|---|---|

|

Type I |

Smoke/Grease |

$16,000+ for 2 – 10′ hoods |

Requires ductwork |

|

Type II |

Heat/Steam |

$900 – $1,700 per foot |

Can skip ductwork |

Technological Advancements in Hood Design

Let’s not forget tech in the kitchen ventilation system. Hoods have come a long way, with energy-efficient designs saving big bucks in the long run. Modern kitchens benefit from commercial kitchen exhaust systems that enhance air quality and safety, ensuring a reliable kitchen environment.

Smart technology can make hood exhaust systems even more amazing, adjusting settings for optimal performance. This includes addressing necessary ventilation and exhaust rates to create a compliant cooking environment. These advances are defining the future of cleaner, smarter kitchens and improving kitchen efficiency.

With features like automatic fire protection and efficient grease filters, these commercial kitchen hood systems not only enhance safety but also support the cooking operations. As we embrace these innovations, we pave the way for a better cooking experience and a safer workplace.

Maintenance Practices for Ventilation Systems

Maintaining your commercial kitchen ventilation system isn’t merely a matter of preference; it’s essential for ensuring a safe cooking environment. Just like a car, regular maintenance of your exhaust system is the best way to ensure everything runs smoothly and safely.

Without proper kitchen ventilation, you risk surprise breakdowns or, even worse, safety issues related to fire hazards and contaminated air. Adhering to commercial kitchen hood code requirements and conducting routine checks can prevent these risks and promote efficient kitchen operations.

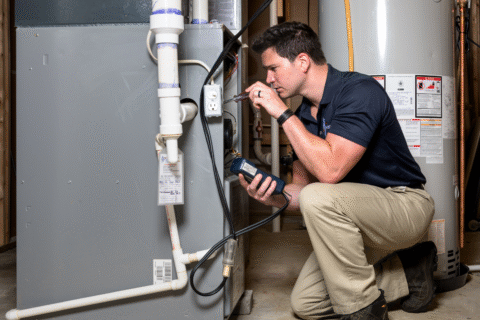

Routine Inspections and Their Importance

Regular inspections of your commercial kitchen ventilation system are key to identifying potential problems before they escalate. How frequently should you review your kitchen exhaust system? You should get a professional check-up every six months. Local codes may require you to visit even more frequently, especially in environments with high cooking volumes where proper kitchen ventilation is crucial.

That’s where inspections catch worn belts and bearings, which are usually to blame for a fan failure in your commercial exhaust hood. Being the first to spot these issues saves you money on repairs and reduces downtime in your commercial kitchen operations.

Plus, staying on top of inspections means you’re following fire safety regulations and keeping your staff and customers safe in a reliable kitchen environment. Ensuring that your exhaust hood systems are compliant not only protects your investment but also upholds the health standards necessary for a successful commercial kitchen.

Professional Cleaning Procedures

Having a proper clean of your ventilation system is just as important.

A clean ventilation system ensures that air quality remains high and that your HVAC system operates efficiently. Dust, allergens, and other pollutants can accumulate in the ducts over time, leading to potential health issues and decreased system performance.

Here’s a quick rundown of what that involves: First, it’s essential to inspect the entire system for any signs of dirt or blockages. This includes checking the ducts, filters, and vents.

Next, professional cleaning may be necessary, especially if significant buildup is observed. This process typically involves using specialized equipment to remove debris and contaminants from the system.

Finally, regular maintenance and cleaning should be scheduled to prevent future issues. Establishing a routine can help maintain optimal air quality and prolong the lifespan of your ventilation system.

-

Steam cleaning the hood: Typically done every six months.

-

Dishwasher cleaning for hood filters: as often as every few days.

-

Mesh filters: Need cleaning at least twice a week.

You want to enlist certified pros because they know your system inside and out. Their expertise is crucial in maintaining the integrity of your heating and cooling systems.

Additionally, certified professionals help prevent scary issues like grease fires. They are trained to identify and mitigate risks that could pose a danger to your home.

Regular cleaning is essential as it increases the system’s safety and efficiency. By ensuring everything is working like a well-oiled machine, you can enjoy a comfortable and safe environment.

Documentation for Compliance

Keeping good, accurate records of maintenance and inspections for your commercial kitchen ventilation system won’t just help you stay smart; it may also be required by law. Maintaining thorough documentation can protect you in case of disputes or audits, especially concerning your commercial kitchen exhaust systems. It also allows you to track the history of your equipment, including hood exhaust systems, and identify patterns that may indicate the need for repairs or replacements.

You’ll want to have records that include dates of inspections, details of maintenance performed on your kitchen exhaust system, and any issues that were identified. Additionally, documenting the personnel involved in the inspections and maintenance can provide further accountability, ensuring compliance with commercial kitchen hood code requirements.

Having these records organized and easily accessible will not only ensure compliance but also enhance your operational efficiency in a commercial kitchen setting. It’s easy to manage these documents when you have inspections and audits. They show that you value safety and adherence to the rules, particularly in relation to fire safety regulations.

Every kitchen should be proud of that commitment to maintaining a reliable kitchen environment. Proper kitchen ventilation is crucial, and keeping accurate records reflects your dedication to commercial kitchen safety standards. By tracking your maintenance, you can ensure that your kitchen appliances and exhaust systems function optimally, providing a safe cooking environment for your staff.

-

Inspection reports

-

Service and cleaning logs

-

Certificates of compliance

In summary, maintaining detailed records is essential for effective kitchen operations. This practice not only supports compliance with necessary ventilation regulations but also fosters a culture of accountability among kitchen operators. Ultimately, a well-documented maintenance history contributes to the overall safety and efficiency of your commercial kitchen.

So, embrace the importance of documentation in your kitchen operations. A proactive approach to maintaining your commercial kitchen exhaust hood systems will help you navigate inspections smoothly and demonstrate your commitment to a compliant cooking environment.

Proactive Role of Equipment Owners

As an owner, you have a lot on the line with your commercial kitchen ventilation system. Training your staff on proper practices is essential, particularly regarding the maintenance of the kitchen exhaust system, which includes cleaning the hood filters. It’s crucial to inform everyone about the importance of proper grease management practices to ensure a compliant cooking environment.

You’re also responsible for ensuring safety in the kitchen. Being proactive means taking steps to maximize vapor capture in your kitchen, such as ensuring that air diffusers are situated at least 10 feet from the exhaust hood. This attention to detail is vital for maintaining good air quality and preventing the buildup of harmful vapors.

This proactive approach not only saves you from potential problems but also keeps your commercial kitchen running smoothly. By adhering to commercial kitchen ventilation design systems and understanding exhaust system requirements, you can create a reliable kitchen environment that prioritizes safety and efficiency.

Benefits of Effective Ventilation

Good ventilation in your commercial kitchen is like the heart of a healthy body—essential and life-giving. A proper commercial kitchen ventilation system ensures a safe cooking environment by effectively removing cooking vapors and airborne pollutants. It’s not just about compliance; it’s about making a workplace that’s comfortable and efficient.

A well-designed kitchen ventilation system contributes to fire safety by integrating fire suppression systems and adhering to commercial kitchen hood code requirements. This not only protects kitchen operators but also enhances the overall efficiency of cooking operations. Let’s get into some of the key benefits of having a reliable kitchen environment.

Efficient grease management practices and proper kitchen ventilation are vital for maintaining good air quality. By utilizing commercial kitchen exhaust hoods and exhaust ducts systems, you can ensure that your kitchen operates smoothly while minimizing the risks associated with hazardous cooking effluents.

Enhancing Indoor Air Quality

Good ventilation, especially in a commercial kitchen, means better air quality. In a busy kitchen environment, various smells, smoke, and heat can accumulate, making a reliable kitchen ventilation system essential. A strong exhaust system effectively pulls out harmful pollutants, ensuring the air remains fresh and safe for kitchen operators and staff.

Cleaner air translates to a reduced risk of respiratory problems for the team. When working in a commercial kitchen, it’s crucial to prioritize ventilation to maintain a safe cooking environment. This commitment to proper kitchen ventilation not only promotes health but also fosters a fresh start for the staff every single day.

Moreover, maintaining high air quality is directly tied to kitchen safety. By utilizing effective commercial kitchen exhaust systems, fewer airborne pollutants are present, which minimizes the risks of accidents and health issues, creating a safer workspace for everyone involved in the cooking operations.

Odor Reduction Strategies

There were those smells, too. A reliable kitchen environment requires a solid kitchen ventilation system to help control and filter odors, making cooking more pleasant. Imagine cooking with no remnants of yesterday’s fish fry. By managing cooking vapors and smells through an efficient commercial kitchen exhaust system, the environment remains inviting.

That’s why regular maintenance of your commercial kitchen exhaust hoods is crucial. It’s akin to a tune-up for your car — something necessary to ensure optimal performance. A clean exhaust system, including proper grease management practices, prevents lingering odors, benefiting everyone who enters the kitchen.

Cooling Needs and Cost Reduction Approaches

Now, let’s discuss how to keep things cool in a commercial kitchen. Good kitchen ventilation systems aren’t just about the air; they also help balance out kitchen temperature. During peak cooking operations, kitchens can heat up significantly, making an effective commercial kitchen ventilation system essential. This system manages temperature fluctuations, creating a more pleasant environment for kitchen operators.

A restaurant’s HVAC system can account for a quarter of its total energy usage. By investing in energy-efficient commercial kitchen exhaust systems, you can lead to substantial savings on those bills. Optimizing your ventilation setup not only improves air quality but also ensures compliance with commercial kitchen hood code requirements, which is crucial for safety.

Ultimately, balancing cooling needs with operational costs through a proper kitchen ventilation system can lead to long-term savings. This investment supports efficient grease management practices and reduces the risk of kitchen fires, ensuring a safe cooking environment for all kitchen staff.

Quick Tips for Ventilation Success

-

Regular Maintenance: Keep systems clean to prevent grease buildup.

-

Choose systems that save energy and reduce costs.

-

Air Quality Focus: Ensure systems remove pollutants effectively.

-

Safety First: Prioritize ventilation for a safer kitchen environment.

Conclusion

Good kitchen ventilation isn’t just a rule, but an absolute must. That keeps the air clean and the kitchen safe. Install the correct exhaust systems and keep them maintained regularly. This way you’ll meet the legal requirements, increase staff health, and improve food quality, too. Think of the hood as the understudy in the kitchen. Regular maintenance keeps it in top shape and prevents costly issues. By investing in solid ventilation, you create a better workplace and a more efficient kitchen. Whether you’re setting up a new kitchen or revamping an old one, focus on ventilation. It’s worth it. Want more details or have a query of your own? Explore our resources or get in touch. We’re going to do whatever we can to get your airflow.

Frequently Asked Questions

What Are the Basic Kitchen Ventilation Requirements?

Commercial kitchens require an effective kitchen ventilation system, including proper airflow, commercial kitchen exhaust hoods, and grease filters. These systems help maintain air quality and ensure a safe cooking environment.

How Do Exhaust Systems Work in Commercial Kitchens?

Exhaust systems, including commercial kitchen exhaust systems, effectively remove smoke, steam, and odors through fans and ducts, ensuring a clean and safe cooking environment for kitchen operators.

Why Are Kitchen Hoods Important?

Kitchen hoods, an essential component of a commercial kitchen ventilation system, capture and contain airborne particles while preventing grease and smoke buildup. A good hood exhaust design promotes air quality and lowers the risk of fires.

What Are the Key Maintenance Practices for Ventilation Systems?

Routine cleaning and inspection of your kitchen ventilation system, including filters, ducts, and exhaust fans, are key to maintaining efficiency and extending the life of the commercial kitchen exhaust system.

How Does Effective Ventilation Benefit a Commercial Kitchen?

Proper kitchen ventilation, such as a commercial kitchen ventilation system, reduces heat and odors, improving air quality and creating a safe cooking environment that enhances staff productivity and safety.

Can Poor Ventilation Affect Kitchen Operations?

Poor ventilation in a commercial kitchen is a significant fire hazard and health risk, potentially damaging equipment and increasing energy costs. Prioritizing your kitchen ventilation system is essential for safety and efficiency.

How Often Should Ventilation Systems Be Serviced?

Service your commercial kitchen ventilation system every 3 to 6 months to prevent malfunctions and ensure compliance with safety standards.