Highlands Ranch, CO: Repair and Maintenance for Baseboard Heaters

Key Takeaways

-

If you want to avoid cold spots and expensive breakdowns, get your baseboard heating repaired by scheduling annual check-ups and noting down symptoms for quicker diagnosis.

-

For no heat problems, check boilers, electrical connections, and thermostats initially. Contact a qualified technician when repairs or replacement are outside of small fixes.

-

Irregular heat and odd sounds are usually signs of trapped air, sediment, or faulty parts. Therefore, bleed your radiators, clean out your baseboard units, and schedule a professional check-up if issues continue.

-

If you haven’t already, replace old or obsolete thermostats with new programmable ones and check wiring and calibration to enhance control and energy efficiency.

-

When it comes to repair versus replace, consider the system’s age, how often it needs repair, if replacement parts are readily available, and long-term energy savings. Make the most cost-effective decision.

-

Seasonally, flush hydronic lines, test safety controls, clean units, and keep records. Select licensed local techs who know Highlands Ranch codes.

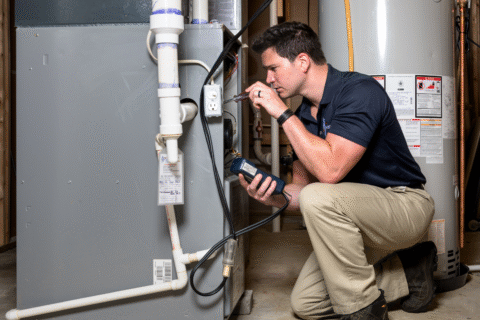

Baseboard heating repair Highlands Ranch — repairing and servicing the low-profile, wall-mounted heaters found in many local homes.

We can calibrate thermostats, replace elements, check hot-water units for leaks, and clean electric units.

By having local technicians, you can receive fast diagnostics, part sourcing, and safety tests to get that even room heat and lower energy use working again.

Prices differ by system and scale, so comparing estimates and guarantees assists in selecting the appropriate services.

Common Issues

Baseboard heaters in Highlands Ranch are very easy to know when they need to be fixed. Knowing those signs allows homeowners to take action before minor faults turn into big expensive issues. Here are the most common problems, why they happen, where they appear, and how to fix them.

1. No Heat

First check your boiler or electric supply. Hydronic systems can be crippled by a failed boiler, weak pilot light or lack of flow of hot water, while electric elements can burn out. Unplug an electrical unit and wait 30 to 60 minutes before any hands-on inspections.

Check thermostats, wiring, and breakers. One bad thermostat can knock multiple heaters on the same circuit offline. Determine whether you need a simple tune-up, a targeted repair, or a full boiler replacement depending on age and symptoms.

Verify that all rooms or zones return to warm after repair to prevent lurking cold pockets.

2. Uneven Heat

Cold rooms and hot rooms indicate blockages, trapped air or sediment. Baseboard units that are blocked by draperies, furniture or clothes impact airflow and performance, and electric heaters need clearances of roughly 3 feet in front, 6 inches on the sides and 12 inches above to work properly.

Bleed hydronic lines to break air pockets, flush boilers to clear sediment and check fins and elements on electric units. Consider zoning and thermostat placement. Poorly placed thermostats or ineffective zone valves can result in inconsistent comfort.

Try system balancing or switching to higher-performance baseboards when design or installation mistakes are stubborn.

3. Strange Noises

Banging, gurgling and whistling typically indicate air in pipes, loose parts or failing components. Gurgling commonly ties to trapped air in hydronic loops. Banging can manifest from expansion in tubing or a failing pump.

Whistling might indicate a blocked vent or narrowed passage. These noises frequently come before leaks or component failure, so arrange an inspection as soon as possible. A trained technician will identify worn pumps, heat-exchanger issues or loose fastenings and suggest repair before damage intensifies.

4. Faulty Thermostat

Test calibration and wiring, first up. Old thermostats can misread temperatures or misfire controls, and if you replace them with programmable, compatible models, you’re good to go.

Make sure the thermostat is compatible with the boiler or electric type, and double-check wiring and settings for multi-zone systems. Yearly inspections help catch drift and avoid multi-heater failure caused by one bad control.

5. Tripped Breaker

Check for a tripped breaker in the electrical panel. Frequent tripping can mean overloaded circuits, bad wiring, or a shorted heater element. Resetting is only secure once you locate the reason.

Older homes may require a complete electrical evaluation and a panel upgrade to accommodate newer boilers and load demands.

Diagnostic Process

A good diagnostic process finds the solution to why baseboard heating in Highlands Ranch is not working or working too little. The simplified steps below describe a process technicians employ, along with some useful checks you can perform at home ahead of their arrival. This list reveals what experts look for and why a detailed examination is important.

-

Visual and basic system check: inspect the boiler, baseboard units, thermostats, and visible piping for signs of damage, leaks, corrosion, or disconnected components. Observe any warning lights or error codes on control panels. Verify power is on, breakers have not tripped, and the system is set to the desired temperature.

Check water pressure for hydronic systems. Low pressure is usually the culprit when there is no heat. If you’ve been ignoring the system, replace the air filter every month for one-inch filters and every six to nine months for four-inch filters as an easy first diagnostic step.

-

Full system test: run the heating through a complete cycle to observe how it starts, reaches temperature, and shuts down. Temperature differences: measure temperature output at various baseboard sections and radiators to detect uneven heat. Hear any weird noises in the boiler, pumps, or piping that indicate air pockets, failing bearings, or sediment.

Utilize diagnostic tools to quantify boiler efficiency and combustion where applicable. A furnace acting up quickly makes a home feel cold. These tests show if the issue is output, distribution, or control related.

-

Component isolation and targeted testing: Isolate pumps, zone valves, thermostats, and circulators to test each part on its own. Bypass or actuate valves, or run pumps directly to determine which fails under direct control. Only replace or repair the failing parts to minimize disruption and expense.

Document every part you check, how you do it, and what you find for maintenance records.

-

Documentation and follow-up: Log symptoms, dates, temperatures, and error codes. Photograph visible problems and record any homeowner comments, for example, when it occurs and whether it tracks with colder outdoor temps. Preventive professional visits can catch small problems before they become big ones and save you money.

Plan annual check-ups to detect wear before it causes breakdown. Technicians employ specialized tools, including pressure gauges, infrared thermometers, combustion analyzers, and multimeters, to improve diagnostic precision. Good records make for fast service and better results. Knowing how your home’s heat works is the key to keeping it efficient and dependable.

Initial Check

Begin with a boiler, baseboard, and thermostat ‘eye ball’ diagnostic. Check power, water pressure and settings to eliminate the obvious. Check for leaks, corrosion, or disconnected parts of the hydronic heating system.

Write down any error codes or warning lights the system provides for the technician.

System Test

Take the furnace for a test run through an entire heat cycle to catch mechanical gremlins and performance quirks. Check temperature output at a few places, including radiators and baseboard units, for uneven heating.

Listen for odd sounds or indications of insufficient airflow when running. Diagnostic tools measure boiler efficiency and hidden faults.

Component Isolation

Try to isolate pumps, valves, thermostats, and other components to determine which parts are damaged. Test each section of the system individually to localize the issue.

Swap or fix only the broken piece to reduce waste and expense. Record what was tested and the results for future servicing purposes.

Repair or Replace?

Deciding whether to repair or replace a baseboard heating system hinges on a few clear factors. A focused assessment comes first, then matching options to goals: lower bills, steady heat, or short-term fixes. Below are criteria to guide that choice.

-

System age and typical expected lifespan

-

Recent repair history and frequency of breakdowns

-

Type and expense of existing damage (leaks, noise, low pressure)

-

Efficiency rating and fuel type of the boiler

-

Parts availability and labor rates in the local market

-

Long-term savings from a high-efficiency replacement

-

Impact on comfort: cold spots, uneven heat, noise levels

-

Timeframe for return on investment and available budget

System Age

Check boiler and baseboard for remaining life. Older boilers frequently don’t have modern controls and are run at lower efficiency. If your unit is close to or beyond the usual life expectancies, replacement sounds quite reasonable.

A boiler that is 15 to 20 years old, for instance, may consume significantly more fuel than new condensing designs and cost more in parts. New machinery has smaller footprints, quieter motors and more advanced controls.

Smart thermostats and modulating boilers provide more consistent heat and reduce fuel consumption, which is important in places where bills are a monthly stress. If the system exhibits symptoms such as uneven heat or radiators that won’t warm, age tips the scale toward replacement.

Repair Cost

|

Item |

Typical cost range (currency) |

Notes |

|---|---|---|

|

Minor repair (valves, bleed, thermostat) |

80–400 |

Fast fixes, lower parts cost |

|

Major repair (pump, heat exchanger) |

400–2,000 |

Parts may be costly on older units |

|

Full replacement (boiler + labor) |

2,500–7,500 |

Varies by capacity and efficiency |

Factor labor rates and parts lead times when you’re comparing numbers. Certain legacy systems have limited parts available, which drives up both the expense and the downtime.

Too many minor repairs lead to rising costs, and three return calls in a heating season usually make replacement economical. Calculate payback by comparing the higher upfront cost against ongoing repair spending plus efficiency gains.

Energy Bills

Check recent energy bills for mysterious spikes or consistent upward creep. Those tend to indicate a system that’s losing efficiency. Boilers might require annual maintenance, cleaning, combustion tuning, and component checks to bring them back up to performance, which is less expensive than replacement.

If bills are still high after service, a high-efficiency boiler is the next step in reducing consumption and delivering more constant heat. Track monthly usage pre/post interventions to gauge impact.

Pair upgrades, better controls, pipe insulation, and rudimentary zoning with a new boiler to accelerate payback. Measure cuts in fuel consumption as the most obvious indicator of success and relief.

Local Considerations

Highlands Ranch and the greater Denver metro area offer a blend of climate, code and site-specific influences that dictate baseboard heating repair decisions. Think local with your repair or upgrade — weather patterns, altitude, water purity, neighborhood restrictions! The advice below dissects these factors into actionable tips and steps.

Climate Impact

Winters get cold and cold snaps are sudden and summers can be hot. Systems should provide warmth quickly and continue to operate while under duress from the extremes. Because heat needs to arrive fast, that frequently translates into well-sized boilers and efficient hydronic distribution systems.

Too-big equipment wastes energy and too-small units fail in deep cold. Insulation matters; add or upgrade wall and pipe insulation to reduce heat loss and shorten run times. Good heat exchangers are not ruined by frequent cycling and hold output. Select materials rated for local water chemistry.

Seasonal tune-ups before winter and after summer catch wear from temperature swings. Tune-ups consist of combustion checks, thermostat calibration, leak inspection, and flushing low spots in baseboard loops. In high-altitude communities, combustion environments and venting require modification for safe functioning.

Brownouts are a real threat. Consider battery-backed controls or backup generators for critical systems. Hard water and minerals can scale and corrode. Test local water and add treatment, such as softeners or chemical inhibitors, as necessary. Water quality impacts maintenance intervals and heat exchanger life.

Building Codes

|

Item |

Why it matters |

Action for homeowners |

|---|---|---|

|

Permits & Inspections |

Required for safety and resale value |

Obtain permits; schedule inspections |

|

Electrical requirements |

Proper wiring and breakers protect systems |

Use licensed electricians for upgrades |

|

Venting & combustion |

Prevents carbon monoxide risks |

Follow vent sizing and clearances in code |

|

Noise & HOA rules |

May limit equipment placement or sound |

Check HOA rules before installation |

|

Altitude adjustments |

Affects combustion and system sizing |

Inform installer of elevation for proper setup |

Codes are evolving, so keep up to date on boiler, electrical, and venting regulations. Cooperate with licensed plumbers and electricians to satisfy standards and prevent failed inspections.

Checklist: confirm permits, verify venting clearances, confirm electrical service capacity, document HOA constraints, and secure inspection sign-off.

Technician Credentials

Check for certifications and proven experience with hydronic systems and boiler repair. Request local referrals in Highlands Ranch or Denver metro to verify they know the area codes and altitude.

Ask for proof of licensing, insurance, and ongoing training. These shield you from liability and demonstrate professional standards. Opt for companies that demonstrate a history of taking care with seasonal tune-ups and emergency service.

Experienced electricians and plumbers save you expensive rework and make sure you’re up to code. Partnering with pros typically means extended equipment life, safer operation and eligibility for local rebates or incentives for high-efficiency upgrades.

Cost Factors

Baseboard heating repair costs depend on a few key factors. Knowing these can assist homeowners in Highlands Ranch and beyond anticipate costs and determine whether to repair, partially replace, or completely upgrade. Here are the major cost factors and some actionable observations on each.

Labor Rates

Technician expertise and brand reputation influence labor fees. An apprentice or junior tech will be cheaper per hour than a credentialed expert with decades of tenure. Emergency or after-hours work increases fees. Anticipate a premium rate of 20% to 50% for nights, weekends, or holidays.

One flat repair call during regular hours could be substantially less expensive than the same call after midnight. At least 3 HVAC or electrical specialists for competitive pricing. Inquire about hourly rates, minimums and if diagnostic fees get credited to the final bill.

Plan regular checkups at off-peak hours to evade the surcharge. Lots of businesses provide cheaper weekday morning times that are less expensive than weekend times. Ask for itemized quotes that break out parts from labor. That makes it easier to gauge where savings are possible and to negotiate or shop parts yourself where allowable.

Part Availability

Replacement parts can be a cost factor as well as repair time. Common parts, like heating elements at around 20 to 40 USD, are inexpensive but can still require time to install. If we have a part in stock, repair turns around faster and total cost remains lower.

If a part needs to be special-ordered, which is typical with aged or uncommon boiler units, anticipate extra shipping charges and wait times. Work with firms that maintain a wide stock so you don’t have to wait. For older systems where parts are continually difficult to source, think about upgrading system components or replacing the system.

In the long run, repeated special orders will usually cost more than a premeditated replacement.

System Complexity

Multizone systems, radiant floor loops, integrated controls, or combined HVAC functions make repairs more complex. New boilers with smart controls or networked thermostats need technicians with specialized training and that expertise commands a higher labor rate.

Basic electric baseboard heater repair might average 287 USD with most repairs between 139 and 440 USD. Replacing a wall heater often costs between 380 and 1,000 USD. Consider local electricity rates when deciding.

Electric baseboards can add around $50 to $60 a month per unit in cold months, and areas with rates that are up to 50% above national averages increase operating costs. Write down system configuration and specifications now to accelerate future servicing and eliminate diagnostic delays.

Proactive Maintenance

Proactive maintenance consists of periodic checkups and tune-ups to keep baseboard heating running smoothly and avoid surprise malfunctions. It generally catches minor defects early, enhances performance, and lowers repair expenses in the future.

Here’s a short list of fundamental tasks homeowners should rely on to prepare systems seasonally and care for them long term:

-

Clean baseboard covers and remove blockages

-

Flush hydronic loops to remove sediment

-

Test thermostats, safety controls, and pressure relief valves

-

Change air and hydronic filters on a set schedule

-

Set up yearly furnace or boiler tune-ups with a reliable HVAC company.

-

Monitor for leaks, corrosion, and unusual noises

-

Track performance data and record all maintenance actions

-

Consider upgrades: high-efficiency boiler, smart thermostat

Seasonal Prep

Checklist for seasonal readiness: inspect covers and fins for dust, vacuum inside units, confirm no furniture blocks convectors, and verify paint or debris isn’t trapping heat.

Flush closed-loop hydronic systems of sediment and sludge that slow flow and reduce heat transfer. Follow manufacturer guidance or hire a pro if you lack the tools.

Test thermostats, safety controls, and pressure relief valves to ensure they trip and reset properly. Malfunctioning controls can result in overheating or hazardous pressure accumulation.

Proactively maintain your baseboard units. Use a brush or low-suction vacuum to clean baseboard heaters and check for pet hair or small objects blocking airflow. A quick thermometer sweep of every room can reveal uneven heating and indicate trapped air or flow issues.

Long-Term Care

Remind yourself of annual boiler or furnace tune-ups and filter changes. Plan them on a calendar and tie them to a service contract with a trusted local HVAC company to maintain consistency and get priority service.

Check system performance and repair small leaks or strange noises immediately. A slow drip can point to a failing valve and clanks can indicate air in the lines.

Take the time to invest in upgrades like high-efficiency boilers or smart thermostats that reduce energy consumption and keep you comfortable. A modulating boiler combined with zoning controls saves real money over time.

Maintain a maintenance diary. Note dates, symptoms, parts replaced and technicians’ names to help diagnose trends and schedule future upgrades. It can be more time and resource intensive, but it frequently averts expensive catastrophic failure and enables forecastable budgets.

Tracking performance information, even rudimentary run-time logs, aids in sensing when something is acting strangely and forecasting when a part will break so homeowners can schedule maintenance instead of responding to emergencies.

Conclusion

Baseboard heating Highlands Ranch requires consistent attention. Standard inspections even out heat and reduce bill shocks. Small leaks, noisy fins, and poor circulation remain small if caught quickly. A clear diagnostic step by step saves time and cost: check power, inspect pipes, test valves, and flush the system. Select repair for worn components that still function and select replacement for rusted fins, multiple leaks, or uneven heat between rooms. Local weather and contractor rates determine the ultimate cost. Keep a simple maintenance plan: flush once a year, bleed zones, and clean vents. For assistance, schedule a certified local technician for a quick inspection. Book service now to stay warm and safe in your home.

Frequently Asked Questions

What are common signs my baseboard heater needs repair?

Look for uneven heat, cold spots, weird noises, visible leaks or a sudden spike in your energy bills. These signs are symptoms of parts failure or circulation problems that require immediate servicing.

How does a professional diagnose baseboard heating issues?

A technician makes an inspection of valves, pipes, thermostats and boiler. They employ pressure and flow tests along with thermal checks to identify leaks, airlocks or control failures.

When should I replace rather than repair my baseboard heater?

Replace your system if it is older than 20 to 25 years, has had repeated failures, or if parts are obsolete. Replacement makes it more reliable and more energy efficient.

How do local factors in Highlands Ranch affect repairs?

Altitude, water hardness and codes can impact corrosion, scale and permits. A local pro will factor these into diagnosis and repair.

What are the main cost factors for baseboard heating repair?

Prices vary based on labor, parts (valves, fins, thermostats), amount of piping work and accessibility. Emergency visits and permits add to the cost.

How often should I perform proactive maintenance?

Have a technician come out to inspect and bleed radiators or zones annually. Periodic inspections minimize failures and increase system longevity.

Can I safely do minor baseboard heating repairs myself?

Easy stuff like cleaning fins or bleeding air can be DIY if you use safety steps. For leaks, wiring, or boiler work, get a professional.