Restaurant Grease Trap Cleaning South Denver Cleaning, Installation & Maintenance

Key Takeaways

-

Regular cleaning is essential to preventing costly sewer backups and regulatory fines. Schedule professional grease trap cleaning at appropriate intervals and maintain cleaning logs for inspections.

-

Professional service on a regular schedule that includes pumping, scraping, inspection and proper disposal prolongs equipment life and minimizes emergency repairs. Follow up on pump-out dates and inspection results.

-

Clean grease traps guard food safety and public health. Educate employees on appropriate disposal methods and clean adjacent areas to minimize infection and vermin.

-

South Denver’s climate and local rules influence how often and by what methods we service your trap. Modify winter schedules, insulate your outdoor traps, and verify local water district and municipal regulations.

-

Select someone with local experience, who’s licensed and insured and who has documented disposal practices. Ask for references and manifests before you hire.

-

Routine care is the key to a more efficient kitchen, long-term cost reduction, odor control, and regulatory compliance. Budget with regular service and incorporate trap inspections into daily habits.

Restaurant grease trap cleaning south denver is the regular removal of fats, oils, and solids from kitchen waste in the South Denver area. Local services observe health codes and avoid blockages, stinky odors, and expensive backups.

Our licensed technicians perform measured pumping and safe disposal that conforms to municipal regulations. Regular schedules reduce fire hazards and plumbing repairs while keeping kitchens code-compliant.

Below are costs, frequency, and trusted local providers.

The Unseen Necessity

Grease traps are a small but essential kitchen infrastructure. They prevent FOG from getting into the sewer system, shield municipal pipes, and preserve local water quality. It’s a regulation enforced by local authorities to safeguard city infrastructure and waterways.

In South Denver and other high-elevation cities, temperature swings and lower atmospheric pressure alter the rate at which grease solidifies, causing traps to clog sooner and demanding more frequent service intervals.

1. Preventing Fines

Weekly cleaning keeps restaurants in compliance with local waste ordinances and state laws that mandate proper FOG disposal. Violations can lead to varied penalties including civil fines, mandatory corrective work orders, or criminal charges in severe or repeated cases.

They can be as minor as administrative fines or large penalties and even suspensions of service licenses. Keep cleaning logs with dates, hauler names, volume removed, and disposal receipts. This is valuable to inspectors.

Use digital tools to automate reminders and maintain audit-ready documentation. Clinical operators now use cloud logs that timestamp service and affix waste-hauler permits.

2. Avoiding Backups

FOG accumulates on trap walls and in downstream piping until flow is impeded. That blockage makes sluggish drains, gurgles, putrid backups, and kitchen floods at rush hour.

It’s emergency shutdowns that cost lost revenue and emergency plumber fees. Watch for early warning signs: persistent slow drainage, strong sewer odors near sinks, and bubbles in floor drains.

This is where a maintenance checklist is helpful. Think daily skimming, weekly solids removal, and monthly professional pump-outs. Plan on more frequent service in the winter when grease congeals more quickly.

3. Protecting Health

Dirty grease traps become breeding grounds for bacteria and attract pests such as flies and rodents, which increases the risk of food contamination. Overflowing traps can lead to cross contamination if waste makes its way to prep areas.

Train staff on proper grease handling: strainers, oil-only containers, and immediate clean-up of spills. Sanitize around the trap and keep lids sealed to minimize odors and vector access.

Utilize authorized waste haulers for disposal. Dumping can prompt regulatory intervention and environmental damage.

4. Upholding Reputation

Surface grease, smells, or inspection flunks kill customer confidence and fuel bad web buzz. Just one health citation in the press can drop bookings and sales.

How do you know when it is cleaned? Track feedback loops for odor or cleanliness complaints and address immediately with proof of remediation.

5. Ensuring Compliance

Local and federal regulations provide unambiguous guidelines concerning trap dimension, cleaning frequency and disposal of refuse. Maintain proper service logs and work with certified technicians and licensed waste haulers.

Non-compliance means fines, forced closures or the loss of a license. Preventing is much cheaper than recovering.

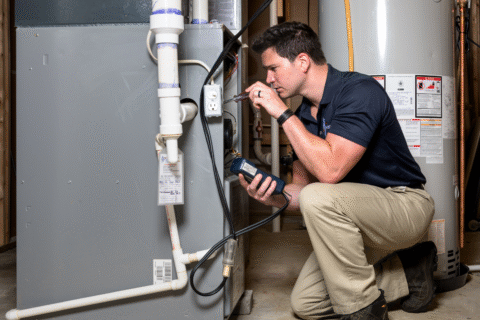

The Professional Method

Large restaurant grease traps, particularly those units between 500 and 2,500 gallons, demand a professional method. Professionals employ a standardized process to purge built-up FOG, solids, and wastewater in a safe manner and maintain trap content underneath typical regulatory thresholds, typically 25% FOG.

The professional method mixes daily maintenance, periodic pump-outs, manual labor, inspection, and controlled disposal. These are the work phases and concrete specifics for each.

Pumping

Pumping extracts trapped grease, solids, and wastewater out of the unit. Technicians vacuum the trap to as close to dry as possible, leaving very little residue. For big traps, this usually means vacuum trucks and pumps designed for highly viscous materials.

Log pump-out dates to maintain a regular schedule. Many professionals suggest every 4 to 6 weeks for hectic kitchens. Partial pumping, which leaves a thick layer of sludge or greasy water, leads to faster buildup and can push the trap over 25 percent FOG well ahead of the next service.

Scraping

Scraping removes the carbonized grease deposits from walls, baffles, and fixtures. After pumping, crews utilize nonmetal and metal scrapers to remove crust without nicking cast iron or plastic.

Manual scraping must be done occasionally to clear out stubborn deposits and prevent blockage from reoccurring. Mind corners and baffle edges; missed patches of solid grease dry and harden, which lowers capacity.

Examine during scraping for corrosion, thin metal, or damaged seals, as scraping reveals weak places that can leak or snap off under pressure.

Inspection

Use a checklist to confirm a full-service clean: pump-out date and volume removed, visible FOG percentage, condition of baffles and lids, inlet and outlet flow, signs of corrosion or cracks, gasket condition, and nearby drain performance.

Log discoveries with time-stamped notes and photos for repair documentation and compliance evidence. Being proactive about replacing worn parts or slow drainage before it becomes a problem saves on major repairs and avoids noncompliance fines.

Schedule professional inspections between cleanings for hectic operations or following any abnormal back-ups.

Disposal

Dispose of grease trap waste pursuant to local rules and environmental law. Let licensed waste haulers take care of the transport and processing.

Request manifest and disposal receipts as confirmation. Fly dumping carries large fines and environmental consequences. Pros typically cool hot grey water.

Give it around ten minutes after ejection from dishwashers or sinks prior to pouring to minimize steam and splatter hazards. Taking out pounds of grease and sludge is hard physical work and a mess.

Professional crews with appropriate PPE and equipment reduce risk and guarantee legal disposal.

South Denver’s Demands

South Denver’s weather, altitude, and regulations influence restaurants’ grease trap servicing. Operators need to juggle environmental issues, city and water district regulations, and down-to-earth problems like freezing winter temperatures and off-hours service to maintain systems and keep sewers flowing.

Climate Impact

Cold weather accelerates grease solidification, increasing clogging potential because FOG hardens more quickly than it does in warm weather. High altitude reduces the boiling point of water, which can alter how fast grease separates and solidifies in the trap. Hence, predictability decreases versus sea-level systems.

Winter months therefore need more frequent cleanings. Aim to check traps monthly to bi-monthly in cold spells and when 25% of depth is reached, whichever comes first.

Insulating outdoor grease traps diminishes temperature swings and delays solidification during night. Insulation can be the rigid foam encasing your body or insulated lids with weather seals. In both cases, they reduce freeze-thaw stress on seals and piping.

Keep an eye on them around spring thaw and cold snaps; they will expose a lurking blockage. Basic flow tests and visual inspections post-hurricane capture problems early.

Local Codes

|

Code area |

Requirement |

|---|---|

|

Cleaning trigger |

Clean when 25% of trap depth is FOG/solids or every 90 days minimum |

|

Record keeping |

Maintain maintenance logs for at least three years |

|

Installation |

Permits required for new or replaced traps; meet setback and size rules |

|

Inspections |

City may inspect on complaint or routine schedule |

Check code updates often – municipal rules change and a missed amendment can get you fined! City and county differences matter: county health departments may add requirements for certain neighborhoods or business types.

When language is ambiguous, check with local permitting offices or the city environmental services desk for written instructions.

Water District Rules

Water districts limit grease discharge to preserve the health of their treatment plants and streams, so they often require pre-treatment, permits for installation, and defined sampling procedures. Make sure you own the trap.

Obtain permits before you install or modify a trap to prevent stop-work orders. Maintain maintenance and disposal records as most districts demand you log service dates, volumes removed, and hauler information.

Reporting and record-keeping defend you against enforcement. Violations can result in fines, forced closures, and expensive cleanup of sewer back-ups.

For high-grease-load restaurants, such as fry houses and bakeries, anticipate stricter monitoring and less time permitted between cleanings.

Choosing Your Service

Selecting Your Service

Focus on measurable elements: experience, licensing, disposal practices, inspection routines, equipment, response time, and local regulatory knowledge. Compare quotes only after you’ve verified a pre-service inspection and written estimate.

Maintain contracts and disposal receipts for audits.

Experience

Go with companies that have a history with commercial kitchen grease and a customer base of restaurants. Inquire how long they have been serving the food-service industry.

Ask for comparable jobs in size and volume to your operation. Pro technicians find sneaky problems quickly, such as compromised baffles, vent blockages, and grease migration in connected drains, minimizing callbacks.

Ask about training and certifications. Employees who train in industrial cleaning techniques and safety minimize downtime and safeguard employees and customers. Most will do an in-person inspection prior to quoting.

Demand this so the quote represents real scope, not guesswork. If your kitchen is high volume, seek out companies that suggest and are capable of delivering biannual or quarterly schedules.

Some operators elect to clean twice annually, while others clean every 90 days or less, depending on usage and local regulations.

Licensing

Verify that the company has all necessary state and local licenses for sewer and waste work and request copies. Liability and workers’ compensation insurance is important to safeguard your business if a worker is injured or damage occurs during service.

Ensure techs are certified for hazardous waste when necessary, as some grease and wastewater is deemed regulated material under certain codes. Ask for this documentation and make it a condition before permitting work on site.

A licensed company will generally have a good understanding of South Denver regulations and can help you understand how often you need permits and what fines to expect if you don’t.

Disposal Practices

Verify that the company is responsible in their waste disposal and can demonstrate contracts with authorized waste processors. Verify that they haul waste to locations approved by the municipal government and have documentation of legal compliance.

Query how they track chain of custody and if they provide disposal receipts post jobs. Keep those receipts for auditing and inspections.

Go for companies with specialized cleaning techniques and high-tech equipment since the better the gear, the more thorough the grease removal and the longer you can wait between cleanings.

Schedule regular service. Booking it last minute can lead to fines or shutdown if inspections catch you before you’ve serviced.

Beyond Maintenance

It connects to kitchen flow, long term expenses, odor and pest control, compliance status, and environmental conservation. Here are some fundamental advantages of routine grease trap servicing for eateries in South Denver and other metropolitan areas.

-

Reduces chance of blockages and emergency plumbing work.

-

Improves wastewater flow and lowers utility use.

-

Cuts fines and compliance risks tied to municipal codes.

-

Limits odors and pest attraction near the kitchen.

-

Protects local waterways by keeping FOG out of drains.

-

Supports sustainability goals and reporting for facilities.

-

Enables better staff safety and fewer slip hazards.

-

Provides documentation useful for audits and insurance claims.

Kitchen Efficiency

Free and clean grease traps allow the wastewater to flow faster through the sinks and drains, lessening slow draining sinks and the necessity to close lines for repairs. Drains that clear backups faster mean less time clearing backups, so cooks and dish staff can stay at work instead of waiting on maintenance.

Add a quick visual inspection to your daily opening and closing procedures. Observe the grease level and any floating solids. Let those check-up data tell you when to schedule your deep cleans and keep you out of the peak hour service.

Somewhat more advanced facility managers integrate those checks into digital records so scheduling software can display real-time status and assist in organizing team shifts around service windows.

Cost Savings

Routine service reduces the likelihood of last-minute plumbing dashes, which cost multiple times as much as planned cleanings. Consider that a reactive repair can be three to ten times or more a routine pump-out, depending on the severity.

Optimized drainage further minimizes hot water consumption and alleviates pump burden, thereby reducing utility and maintenance costs in the long run. Monitor maintenance expenditures compared to fines and repair bills avoided.

Some locations employ scheduling software to measure ROI and demonstrate value to ownership. Budgeting for predictable, scheduled service smooths your cash flow and avoids sudden, large expenses.

Odor Control

Regular cleaning gets rid of the residues that create gross kitchen odors and helps manage kitchen pests attracted to food waste. Seal traps and ensure proper ventilation to keep odors from migrating into customer areas.

Enzyme treatments can be a nice addition but should never replace mechanical cleaning. Keep an eye on the air quality around waste lines and vent outsides for early problems. Little changes in smell usually come before a big issue.

Denver’s altitude and temperature swings can solidify grease more quickly, which is why we recommend checking traps more frequently during the colder months.

Proper Installation

Proper installation lays the foundation for long-term performance, regulatory compliance, and environmental protection. Planning ahead prior to installation minimizes downtime and the potential for sewer contamination. The following subsections cover the main decisions: sizing, location, and materials, with examples and practical steps for new or renovated kitchens.

Sizing

|

Kitchen Size / Output |

Typical Trap Size (liters) |

Notes |

|---|---|---|

|

Small café, 1–3 fixtures |

~190 L (50 gallons) |

Common commercial kitchen baseline |

|

Medium restaurant, 4–8 fixtures |

380–760 L |

May need 2 traps or a larger interceptor |

|

Large kitchen, 9+ fixtures or high output |

1000–19,000 L (up to 5,000 gal) |

Consider outdoor interceptors for heavy loads |

Undersized traps fill quickly and cause additional cleanings. Traps of approximately 190 L (50 gallons) are standard in kitchens but can fill to 30% capacity rapidly in high-traffic locations. Cleaning when capacity reaches 30% is good practice.

Use manufacturer sizing charts or flow-rate equations. Save the calculation and rationale in project files for inspectors. See manufacturer tables and run-throughs with your plumber. Record fixture counts, flow estimates, and selected capacity. It aids in audits and future upgrades.

Location

Select a location that facilitates simple removal for regular cleaning and inspection. Inside traps should sit where service vehicles or staff can access the cover without repositioning heavy machinery. Outdoor interceptors must be provided with unobstructed access and safe ground.

Don’t put it near heat sources or busy walkways. Heat can alter the viscosity of the grease, disrupting separation, and busy walkways can make removal difficult and hazardous.

Work with your plumbing contractor for location so that inlet and outlet slopes remain optimal. A bad slope or long runs stop up flow and cause solids to settle in front of the trap. Identify the precise trap location on kitchen floor plans and tag on-site for employees and inspectors.

Materials

Opt for corrosion-resistant materials such as stainless steel or reinforced thermoplastic. Stainless gives it longevity and is standard for indoor traps. Plastic may be lighter and economical for some sizes, but verify UV and crush resistance for outdoor use.

Compare cost, expected life, and maintenance. Stainless might be more expensive initially but usually outlives other materials with less maintenance. Check that materials comply with local health and safety regulations for food establishments and demand manufacturers’ guarantees to protect against breakdowns.

Hydro-jet cleaning of food byproducts and grease stack up is a suggested service. For large-capacity interceptors up to 19,000 liters (5,000 gallons), design for specialized access and a frequent cleaning routine every 90 days or less, as several local regulations demand.

Our routine treatment keeps sewers from overflowing and polluting.

Conclusion

Restaurant grease trap cleaning south denver Regular cleanings prevent clogs, reduce fines and keep drains clear. South Denver, CO restaurant grease trap cleaning – water rules and freezing weather alter the frequency of cleaning. Choose a neighborhood expert with measured pumps, transparent reports and responsible waste hauling. Find certified techs, good references and a schedule that matches your menu and hours.

Include checks following major events or menu changes. Combine cleaning with assay tests and staff measures, such as daily skimming and grease bins. Little things like trap covers and flow control add life and reduce expenses.

Need a fast estimate for some local service or a clean date that fits your shift. Call a reliable provider and receive a personalized plan.

Frequently Asked Questions

What is a grease trap and why is it necessary for restaurants?

A grease trap collects fats, oils, and grease before they reach the sewer. It keeps clogs, stink, and plumbing tickets at bay. Routine cleaning maintains kitchens running and in line with health and environmental regulations.

How often should a restaurant in South Denver clean its grease trap?

Most restaurants clean every one to three months. How often depends on kitchen size, menu, and local regulations. High-grease operations require more frequent service to prevent backups and fines.

What does professional grease trap cleaning include?

Experts pump waste out, scrape the inner walls, measure the trap depth, and give a written report. They check for damage and can recommend maintenance or upgrades to comply with local codes.

Are there local regulations in South Denver I should know about?

Yes. South Denver adheres to municipal and state wastewater regulations. Permits, recordkeeping, and disposal standards usually come into play. Hire a licensed service that knows the local codes to remain compliant.

How much does professional grease trap cleaning typically cost?

Pricing depends on trap size, access, and service frequency. Anticipate a sliding scale based on cubic volume and difficulty. Receive written estimates from licensed providers for precise pricing.

Can poor installation cause recurring grease trap problems?

Yes. Improper slope, incorrect trap size or poor venting all create backups and frequent clogs. Correct installation means less maintenance, longer service life and lower costs over time.

How can I reduce grease buildup between cleanings?

Have staff scrape plates, use drain strainers and don’t pour grease down drains. Or at least sign up for a grease recycling program and have a professional clean regularly to reduce buildup.