Water Hammer: Causes, Effects, and How to Prevent It

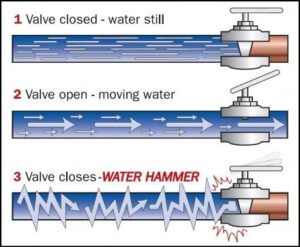

Water hammer is a common plumbing issue caused by a pressure wave that can occur when you close taps, leading to loud banging noises in your pipes, often related to faulty washers or a malfunctioning float valve. This phenomenon occurs when water flow suddenly stops or changes direction, creating shock waves. It has been a concern since the early days of plumbing, affecting homes and buildings alike.

Understanding the causes of water hammer is essential for homeowners. Factors like high water pressure, fast-closing valves, and inadequate pipe support contribute to this problem. Fortunately, there are effective solutions available. By addressing these issues, you can minimize noise and prevent potential damage to your plumbing system. Let’s dive into the causes and solutions, including the valve, to keep your home quiet and safe.

Key Takeaways

-

Water hammer is a common plumbing issue caused by sudden changes in water flow, leading to loud banging noises in pipes.

-

To reduce water hammer, consider securing and insulating your pipes to minimize movement and vibrations.

-

Installing air chambers can absorb shock waves from fast-moving water, helping to prevent the banging sound.

-

Water hammer arrestors are devices designed specifically to dampen the noise and pressure spikes in your plumbing system.

-

Fast-acting valves can contribute to water hammer; consider replacing them with slower-closing options for smoother transitions.

-

Regular maintenance of your plumbing system, including checking for leaks and securing loose pipes, can help prevent water hammer issues.

Understanding Water Hammer

Definition

Water hammer is a hydraulic shock phenomenon. It occurs when there are sudden changes in water flow due to a valve. This can happen when a valve closes quickly or a pump shuts down abruptly. The sudden stop creates a pressure surge, which travels through the plumbing system.

Causes

Rapid valve closure is a common cause of water hammer. For example, if you turn off a faucet too quickly, the flowing water suddenly stops. This action creates a shock wave that can result in loud banging noises in the pipes. Pump shutdowns also lead to similar effects. When a pump stops suddenly, it causes a rapid change in pressure. This produces the same water hammer effect.

Effects

The water hammer effect can lead to various problems in plumbing systems. It can cause pipes to vibrate and even break. Over time, these shocks can weaken joints and fittings. This may result in leaks or complete pipe failure. Recognizing these issues early is crucial for preventing costly repairs.

Prevention

Preventing water hammer requires careful attention to plumbing design and maintenance. Installing air chambers or water hammer arrestors can help absorb shock waves. These devices create a cushion of air that reduces pressure surges. Regular maintenance of valves and pumps is essential too. Ensuring they operate smoothly minimizes the risk of sudden closures.

Importance of Recognition

Understanding water hammer is vital for homeowners and plumbers alike. Early recognition of symptoms can save money on repairs. Ignoring the problem can lead to severe damage over time. Homeowners should pay attention to unusual noises in their plumbing systems. If banging sounds occur, it’s important to investigate promptly.

Solutions

Several solutions exist for addressing water hammer issues:

-

Install water hammer arrestors.

-

Check valves for proper function.

-

Adjust water pressure settings.

-

Secure loose pipes to minimize movement.

-

Consider professional assessment if problems persist.

Causes of Water Hammer

Loose Pipes

Loose pipes often serve as the main water hammer culprit. They can move or vibrate when water flows through them. This movement creates shock waves, leading to loud banging noises. When pipes are not securely fastened, they can shift with the sudden changes in water pressure.

For example, if a valve closes quickly, it causes a rapid stop in water flow. The loose pipes then rattle against their supports, amplifying the sound. This issue is common in older homes where pipe installation may not meet modern standards. Regular inspection and securing loose pipes can help reduce these noises.

Worn Stop Valves

Worn stop valves also contribute to water hammer problems. These valves control the flow of water in plumbing systems. Over time, they can wear out and fail to close properly. A malfunctioning valve does not stop water flow smoothly. Instead, it can create sudden pressure changes, causing a loud thud.

Components within the valve may become damaged. For instance, rubber seals can wear down or break. This damage leads to leaks and erratic water flow. Replacing worn stop valves can significantly minimize the risk of water hammer.

Entrapped Air

Entrapped air within plumbing systems can further amplify the effects of water hammer. Air pockets create pressure differences that disrupt normal water flow. When water moves past these pockets, it can cause turbulence and shock waves.

These air pockets usually form in high points of piping systems. If not addressed, they can lead to increased noise and vibrations during operation. Flushing the system regularly helps remove trapped air. Installing air chambers or expansion tanks can also prevent this issue.

Effects on Plumbing Systems

Joint Damage

Water hammer can cause severe damage to joints and fittings in plumbing systems. The sudden pressure changes create shock waves that travel through pipes. These ripples increase stress on the connections. Over time, this leads to cracks or ruptures in joints.

These damages are not always visible at first. Homeowners may not notice until a leak occurs. Once a leak starts, it can escalate quickly, leading to major repairs. The cost of fixing these issues adds up fast.

Financial Implications

Repairing ruptured pipes due to pressure buildup can be costly. A simple pipe replacement might seem straightforward, but the reality is different. Labor costs, material expenses, and potential water damage all contribute to the bill.

Emergency plumbing situations arise when leaks develop from damaged pipes. In these cases, homeowners often face unexpected expenses. Insurance may cover some costs, but not all policies include water damage from plumbing issues.

Property Damage Risks

Unnoticed leaks pose significant risks to property infrastructure and equipment. Water leaks can infiltrate walls and floors. This can lead to mold growth, which is harmful to health and expensive to remediate.

Damage does not stop at mold. It can also affect electrical systems and appliances. For instance, a small leak near an electrical outlet can result in dangerous short circuits. Repairing this type of damage often requires additional services from electricians.

Flow Disruption

Water hammer disrupts normal flow within plumbing systems. The rapid pressure changes create problems for appliances like dishwashers and washing machines. These devices rely on steady water flow for optimal performance.

Inconsistent pressure may lead to appliance failure or decreased efficiency. Homeowners might face increased utility bills as appliances work harder than necessary.

Long-Term Consequences

The long-term consequences of water hammer are significant. If left unchecked, the effects compound over time. Repeated stress on pipes leads to more frequent repairs and replacements.

Homeowners may find themselves dealing with ongoing plumbing emergencies as damage worsens. This cycle creates frustration and financial strain.

Preventing Water Hammer Issues

Secure Pipes

Loose pipes can cause significant water hammer problems. When water flows rapidly, these pipes move and vibrate. This movement creates shock waves. Securing and wrapping loose pipes helps to minimize this transmission. Use pipe straps or brackets to hold them tightly against walls or joists.

Insulating the pipes also adds another layer of protection. Foam insulation sleeves are effective in dampening vibrations. This simple step can prevent future headaches related to water hammer.

Install Air-Relief Valves

Air-relief valves are a key component in managing water hammer. Installing these valves at strategic points in your plumbing system allows trapped air to escape. This release reduces pressure buildup when water flow changes suddenly.

Position the valves near fixtures that experience high flow rates, like washing machines and dishwashers. Regular maintenance of these valves is crucial. Make sure they are functioning correctly to ensure maximum effectiveness.

Use Air Chambers

Air chambers serve as cushions for shock waves in plumbing systems. These vertical tubes filled with air absorb sudden changes in water pressure. As the water flow stops abruptly, the air compresses, reducing the impact on the pipes.

Installing air chambers is a straightforward process. They should be placed close to valves and faucets where water hammer issues often occur. Consider checking them periodically for any water accumulation that may affect their performance.

Regular Maintenance

Routine checks of your plumbing system can help identify potential issues early on. Inspecting pipes, fittings, and valves regularly allows you to catch loose components before they become problematic. Address any leaks or signs of wear immediately.

Consider consulting a professional plumber for thorough inspections if needed. They can provide expert advice on specific effective water hammer solutions tailored to your home.

Summary of Solutions

To effectively combat water hammer, consider these solutions:

-

Secure and wrap loose pipes

-

Install air-relief valves

-

Use air chambers

These actions significantly reduce the risk of experiencing water hammer problems in your home.

Securing and Insulating Pipes

Inspecting Pipes

Homeowners should regularly inspect their water supply pipes. Loose pipes can cause significant noise and movement, leading to water hammer issues. Checking for any loose fittings or brackets is essential. Secure these areas to minimize vibrations.

Many homes have pipework that shifts when water flows through. This movement creates a banging sound, often referred to as “noisy pipes.” By ensuring that all connections are tight, homeowners can reduce this problem.

Using Pipe Straps

Using pipe straps or clamps is an effective solution. These tools keep the pipework system firmly in place. They prevent movement and help maintain the integrity of the pipes.

Install straps at regular intervals along the pipes. This action provides support and reduces the chance of local pipeline failure. It also minimizes wear and tear on the pipe joints.

Insulating Pipes

Insulating pipes is another important step. Foam insulation wraps around the pipes, dampening vibrations. This method helps prevent water hammer occurrences by absorbing shocks during sudden changes in water flow.

Insulation also protects against temperature changes. Cold water pipes can sweat, leading to moisture problems in walls and ceilings. Proper insulation prevents this issue while also improving energy efficiency.

Addressing Problem Pipes

e pipes may be more prone to issues than others. Identifying these problem pipes early can save time and money. Homeowners should pay attention to any unusual sounds or vibrations when using water.

If certain sections of pipework seem particularly noisy, consider reinforcing them with additional support. This approach can significantly reduce noise levels and improve overall performance.

Understanding Rigidity

Rigidity plays a crucial role in pipework systems. Flexible pipes can move more easily but may lead to increased noise from water hammer. Rigid pipes, while stable, can transmit vibrations more effectively.

Finding a balance between flexibility and rigidity is key. Homeowners should consult with professionals if unsure about their plumbing system’s setup. Experts can provide tailored advice based on specific conditions.

Pump Considerations

The pump used in a plumbing system affects how water moves through the pipes. A poorly functioning pump can create pressure fluctuations, leading to water hammer effects. Regular maintenance of pumps ensures smooth operation.

Consider upgrading to a variable speed pump for better control over water flow. This upgrade can significantly reduce stress on the entire pipework system.

Installing Air Chambers

Functionality

Air chambers play a crucial role in plumbing systems. They absorb shock waves that occur when water flow is suddenly stopped. This sudden change in pressure can cause loud banging noises, known as water hammer. The air inside the chamber compresses, which helps to cushion the impact of these shock waves.

The entrapped air acts like a spring. When water flows through the pipe and hits a valve, the air chamber absorbs some of this energy. This reduces the stress on pipes and fixtures, preventing damage.

Installation Process

Installing air chambers requires careful planning. First, identify locations near valves where air chambers will be most effective. Typically, they should be placed close to shut-off valves or at the end of long runs of pipe.

-

Turn off the main water supply.

-

Drain the system by opening faucets.

-

Cut into the pipe at the chosen location.

-

Install the chamber using fittings that ensure a proper fitment.

-

Secure it tightly to avoid leaks.

-

Refill the system and check for proper operation.

Positioning is key for effectiveness. If installed incorrectly, air chambers may not function as intended.

Maintenance Needs

Regular maintenance ensures that air chambers remain effective over time. Over time, entrapped air may escape from the chamber, reducing its ability to absorb shock waves.

To maintain them:

-

Periodically check for leaks around fittings.

-

Listen for any signs of water hammer, indicating ineffective chambers.

-

If necessary, recharge the chamber by draining water and refilling it with air.

Foam inserts can also help maintain pressure within chambers, but they require monitoring too.

Properly maintained air chambers can significantly reduce noise and wear in plumbing systems. They provide peace of mind by preventing potential damage caused by water hammer.

Using Water Hammer Arrestors

What Are Arrestors?

Water hammer arrestors are devices that help manage the shocking effects of water movement in pipes. They absorb sudden changes in water pressure, preventing loud banging noises. These devices minimize hydraulic surge and protect plumbing systems from damage.

Installation Process

Installing water hammer arrestors is straightforward. They should be placed near quick-closing water valves. Common locations include washing machines, dishwashers, and toilets.

-

Turn off the water supply.

-

Drain the pipes to remove any remaining water.

-

Cut into the pipe where you will install the arrestor.

-

Attach the arrestor securely using fittings.

-

Restore the water supply and check for leaks.

Proper installation is key to ensuring they work effectively. If done correctly, users will notice a significant reduction in loud hammering sounds.

Benefits of Using Arrestors

Utilizing water hammer arrestors offers several advantages. They help prolong the lifespan of plumbing components by absorbing shock waves from sudden pressure changes. This reduces wear on pipes and fixtures, leading to fewer repairs.

Arrestors also provide a quieter home environment. Noisy water pipes can be disruptive, especially during nighttime hours. By installing these devices, homeowners can enjoy peace without loud hammering sounds interrupting their daily lives.

Water hammer arrestors contribute to overall system efficiency. They prevent excessive stress on plumbing systems caused by high water pressure or rapid valve closures. This efficient operation translates into lower maintenance costs over time.

Real-Life Examples

Many homeowners have experienced issues with noisy pipes due to hydraulic shock. For instance, after installing water hammer arrestors, one family reported a drastic decrease in the hammer sound when turning off their kitchen faucet. Another homeowner noted that their washing machine no longer caused loud banging noises during cycles.

These real-life experiences highlight how effective these devices can be in addressing common plumbing problems.

Addressing Fast-Acting Valves

Valve Types

Fast-acting valves can cause significant water hammer incidents. These valves include solenoid valves, stop valves, and relief valves. Their quick operation can create sudden changes in water flow. This leads to shock waves that produce noise and potential pipe damage.

Evaluating the type of valves in a plumbing system is crucial. Different valves react differently to pressure changes. For example, solenoid valves open and close rapidly. This rapid action increases the risk of water hammer.

System Evaluation

A thorough evaluation of your plumbing system helps identify problematic valves. Inspect all fast-acting valves for their speed and type. Replace or modify those that contribute to water hammer issues.

Float valves are another common type found in many systems. While they serve an important function, they can also act quickly when filling tanks. This rapid action may lead to water hammer if not managed properly.

Solutions for Reduction

To reduce the risk of shock waves, consider these solutions:

-

Replace fast-acting valves with slower alternatives.

-

Install throttling devices to control valve speed.

-

Use pressure-reducing valves to manage flow rates.

These adjustments can minimize sudden pressure changes in the system.

Monitoring Performance

After making modifications, monitor the performance of your plumbing system. Listen for any unusual sounds or vibrations. Regular checks help catch potential issues early before they escalate into larger problems.

Addressing fast-acting valves is essential for preventing water hammer. This proactive approach protects your pipes and fixtures from damage.

Regular Maintenance Tips

Routine Inspections

Homeowners should conduct routine inspections of their plumbing systems. This practice helps identify potential issues before they escalate. Look for signs of wear and tear, especially around joints and fittings. Check for leaks or unusual sounds, such as banging or knocking. These noises often indicate water hammer.

Regular checks can prevent serious problems. A small leak can lead to significant water damage over time. Inspecting pipes every few months is a good habit. It ensures that everything operates smoothly and efficiently.

Signs of Water Hammer

Recognizing the signs of water hammer is crucial. Homeowners may hear loud banging noises when turning off faucets or appliances. This sound occurs due to sudden changes in water movement. Ignoring these signs can lead to more severe issues.

Addressing water hammer promptly is essential. Delaying action can cause damage to pipes and fixtures. Homeowners should take these noises seriously and investigate further. If the sounds persist, it may be time to consult a professional.

Professional Maintenance

Engaging a professional plumber for regular maintenance is vital. Experts can provide an effective solution to potential problems. They have the tools and knowledge to assess the plumbing system thoroughly. Professionals can spot issues that homeowners might overlook.

Scheduled maintenance can enhance system integrity. Plumbers check for high points in the plumbing where air might accumulate. They also ensure that valves function correctly to prevent water hammer. Regular visits can save money in the long run by avoiding costly repairs.

Importance of Maintenance

Maintaining a plumbing system is not just about fixing problems as they arise. It’s about preventing them altogether. Regular maintenance extends the life of pipes and fixtures. It improves overall efficiency, which can reduce water bills.

Homeowners should prioritize this aspect of home care. Simple actions, like checking for leaks and cleaning aerators, can make a difference. Understanding how your plumbing works contributes to better maintenance practices.

Summary

Water hammer can lead to serious plumbing issues if not addressed. You’ve learned about its causes, effects, and various solutions to prevent it. From securing pipes to using water hammer arrestors, there are effective strategies at your disposal. Regular maintenance is crucial to keep your plumbing system in top shape.

Taking action now can save you from costly repairs later. Implement these solutions to ensure a quieter and more efficient plumbing system. Don’t wait for water hammer to disrupt your life—make the necessary changes today for peace of mind. Your home deserves it!

Frequently Asked Questions

What is water hammer?

Water hammer is a plumbing phenomenon characterized by loud banging noises when water flow is suddenly stopped or changed. It occurs due to pressure changes in the pipes, causing vibrations and shockwaves.

What causes water hammer?

Water hammer is primarily caused by fast-closing valves, sudden changes in water flow, or inadequate pipe support. These factors create shockwaves that result in noise and potential damage.

How does water hammer affect plumbing systems?

Water hammer can lead to pipe damage, leaks, and even burst pipes over time. The repeated stress on plumbing systems can shorten their lifespan and increase repair costs.

How can I prevent water hammer?

Preventive measures include securing loose pipes, insulating them, installing air chambers, or using water hammer arrestors. Regular maintenance checks also help identify potential issues early.

What are air chambers?

Air chambers are vertical pipes installed near shut-off valves that absorb shock waves from sudden water flow changes. They help reduce the noise and impact of water hammer.

What are water hammer arrestors?

Water hammer arrestors are devices designed to absorb shock waves in plumbing systems. They act like mini air chambers, providing a cushion to prevent banging sounds and protect pipes.

How often should I maintain my plumbing system?

Regular maintenance should be conducted at least once a year. This includes checking for signs of water hammer, inspecting pipes, and ensuring all fixtures operate smoothly to prevent future issues.